People and fleet equipment are the largest investments that construction companies make. When injuries and accidents happen to either, you lose productivity time, administration costs, and can gain a negative reputation for on-the-job issues. Construction safety management software can protect your people, equipment, and productivity.

Choosing the right safety management program for your business can improve talent recruitment and help retain employees. With a talent shortage in the construction industry, an investment in your construction safety program can offset new hire investments and decrease turnover in your crews. Improve employee loyalty by showing that you care about your people. If online results show an incident or other safety problems, applicants may be discouraged. People want to work for companies that care about protecting their employees. So, how do you select the best construction safety management software for your company?

By digitizing safety records, reporting can be readily available in seconds allowing safety managers to create a proactive safety program where you can stop potential safety issues before something happens.Heavy Construction Systems Specialists Inc.

By digitizing safety records, reporting can be readily available in seconds allowing safety managers to create a proactive safety program where you can stop potential safety issues before something happens.Heavy Construction Systems Specialists Inc.

10 Tips To Select The Right Safety Management Solution

Choose safety management software that:

- Provides digital transformation of manual processes. Instead of waiting days for paper timecards or notes to make it into the office, Foremen can instantly log important safety information—like inspections on each piece of equipment used that day. Safety management software is even more powerful with inspections of equipment being sent straight to the shop.

- Find trends, get proactive, and measure improvements. Do you really understand the results of your safety program? If you’re just looking at stacks of paper, it can be impossible to find trends and measure improvements. By digitizing all your safety records, reporting is accessible in seconds. You can see the big picture, understand what’s really going on, and pivot quickly. Some safety management programs use only forms where a digital safety management program allows you to capture information and report on leading indicators. Leading indicator data can help you create a proactive safety program where you can stop potential safety issues before something happens.

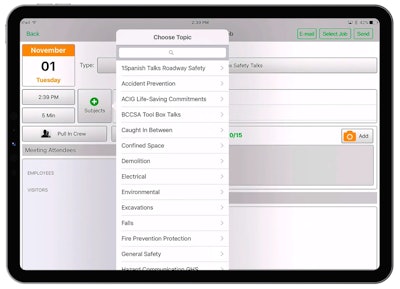

Having a solution that comes pre-loaded with templates can help safety meetings be focused and organized.Heavy Construction Systems Specialists Inc.

Having a solution that comes pre-loaded with templates can help safety meetings be focused and organized.Heavy Construction Systems Specialists Inc. - Helps develop a culture of safety in your crews. Foremen and safety managers are always prepared for the unexpected when your safety management software includes hundreds of toolbox talks, comprehensive inspection reports, crew skill tracking, and safety trend reports that recommend if any specific training topics are needed. Everything logged into your safety management software is saved so it only takes minutes instead of days to make quick reports for external compliance or internal reporting. Whether it’s faulty equipment or obvious defects, downtime can hurt the whole company. When equipment fails due to an ignored mistake, you risk your operation being shut down. With safety management software, Project Managers are always up to date since they receive safety information once it’s submitted and can help take action to protect your people and equipment.

- Offers real-time safety data and reporting for increased communication and fast modification of safety processes. Even if an incident occurs at another jobsite, your team can be alerted to the issue and be ready for a change in plans.

- Comes with hundreds of safety meetings, inspections, and JHA templates, including updated resources for COVID-19 compliance, so your company can get up and running fast. Make sure you can view these meetings, inspections, and templates daily and that information is available on a state and country-specific basis.

- Allows you to keep track of meeting attendees. Foremen can electronically record safety meetings and keep track of attendees by taking their pictures and capturing their signatures. Make sure your safety management software includes built-in safety meetings and will keep track of all previous safety meetings.

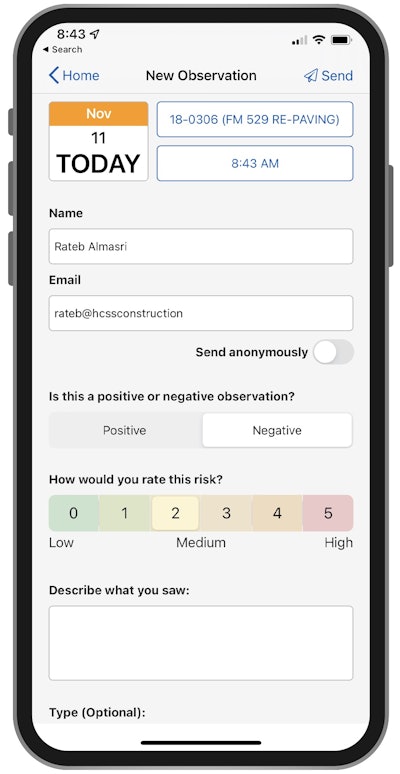

Mobile workforce management software has become essential to helping construction contractors to prevent and curb inherent risks. Simple software user interfaces make it easier to report a safety observation.Heavy Construction Systems Specialists Inc.

Mobile workforce management software has become essential to helping construction contractors to prevent and curb inherent risks. Simple software user interfaces make it easier to report a safety observation.Heavy Construction Systems Specialists Inc. - Includes a mobile app that allows field crews to report site safety inspections in minutes while out in the field. You can also report near-misses to help reduce safety risks.

- Offers an accessible library of inspection templates, allowing the team to perform inspections in the field, or create customized templates for safety inspection of equipment. Keep your inspections all in one place for easy access and reporting purposes.

- Anonymous reporting of unsafe practices. Snitches can prevent stitches by reporting unsafe practices at the jobsite anonymously. If someone observes an unsafe practice, they can scan a QR code posted at the jobsite and anonymously submit their observations. Make sure that reports can be created in both English and Spanish to help bilingual crews communicate more easily.

- Includes OSHA Compliant Incident Reporting. When an incident occurs, your crew lead will fill out all the pertinent information associated with this incident through the incident forms on the app. Once the incident is sent into the office, the safety manager can complete the rest of the incident and append any additional forms, as needed. These reports will be saved permanently for OSHA-compliant recordkeeping.

Many construction firms will integrate their maintenance repair shop software with a safety management solution. As inspections are performed, any failed items can be sent directly to the maintenance software. From there, fleet managers can add the alert to a work order for a repair to be made. The status of the alert can be viewed in the safety software and confirm that repairs were completed. By digitizing this information, paper reports cannot get lost. Bridging communication between the field and the shop will help your team catch potential failures before they happen and prevent equipment downtime.

About the author

Gen Simmons is a technical product manager for HCSS.