Chalk it up to a lack of training, boomers retiring, or the widening skills deficit among available candidates-for-hire, but the construction industry labor shortage continues to swamp industry efforts to take on more work or complete existing projects on time and on schedule.

According to the Associated General Contractors of America, “91% of construction firms are having a hard time finding workers to hire, driving up costs and project delays.” Associated Builders and Contractors share the concern, stating that “the construction industry will need to attract an estimated 501,000 additional workers, on top of the normal pace of hiring in 2024, to meet the demand for labor.”

In response, Equipment Today contacted thought leaders from Caterpillar, Procore, Built Robotics and FORT Robotics to explore some of the ways remote operation and automation technologies are helping to relieve the construction industry labor shortage.

Feeling the Pain

As we surveyed our panel of experts, we found consensus surrounding the negative impact of the labor shortage across the industry. The tight labor market has caused some firms to increase compensation or import talent from outside the area to staff up. Both are expensive options that eventually add substantially to the cost customers pay to keep their projects on track.

Apart from that, many projects simply get pushed back. The delays can run anywhere from six months to several years, stoking demand in an already pent up marketplace.

“New laborers entering the industry nowadays hold all the cards,” said Lauren Lee, communications lead and designer at Built Robotics, a San Francisco-based startup that sells robotic automation solutions to the solar and construction industries. “They want safer working conditions, better pay and enhanced quality of life, all of which points to an influx of technology to transform the way projects get done.”

Without such help, the pressure on crews to perform and produce increases the chance of errors, accidents and rework, none of which is good for business.

“In order to crank out the work using the same number of people and machines,” said Alan Pumklin, Caterpillar product specialist, “you need to work smarter and more efficiently. That’s where technology can make a huge difference.”

Caterpillar has been a pioneer in construction equipment automation and autonomy for many years, most recently offering its “Cat Command station that can operate multiple machines from different product families ... switch from trenching with an excavator, to using a dozer to backfill, then ... picking up a compactor to wrap things up.”

The optimist’s view is that, as technology advances and becomes more prevalent in the industry, the appeal of working in construction will increase among new recruits.

Technology will play an important role in the way the construction industry positions itself in front of incoming generations forming the future workforce.Procore

Technology will play an important role in the way the construction industry positions itself in front of incoming generations forming the future workforce.Procore

“There’s a misguided perception that construction is somehow a fallback career. A dirty job that nobody wants to do. Nothing could be farther from the truth,” says Kris Lengieza, vice president and global tech evangelist at Procore. “As an industry, we need to invest in educating our future workforce with the right skills, tools, and knowledge to hit the ground running. Technology will play a significant role in how we position ourselves and move forward.”

Technology as an Antidote

Over the years, construction site technology has evolved to a place where there are more options than ever, and the capabilities are only improving. From the internet to the cloud to smart phones to global satellite technology, advances are making construction equipment smarter and workers more productive.

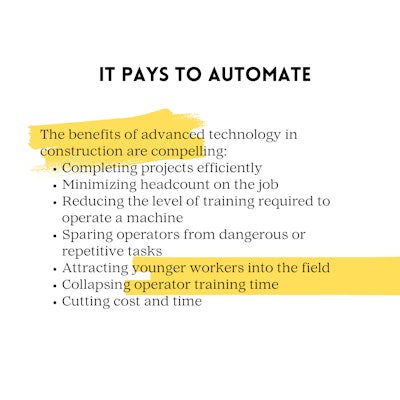

Many government infrastructure projects now call for construction equipment automation, incentivizing vendors to invest in “technology that makes earthmoving and other equipment easier to use, captures production data, or increases safety.” Advances in remote and autonomous construction equipment technology represent a paradigm shift, disrupting the way projects are awarded, managed and performed.

“We’re seeing remote operation from line-of-sight and tele-operation, as well as task automation for repetitive jobs, help skilled laborers focus on tasks where their skills are most needed,” said Doug Riffle, vice president of business development at FORT Robotics, which offers technologies that enable humans and robots to work side-by-side productively and safely. “One unique thing that people like about our remote control options is that they take their design inspiration from video game-style remote controls. This makes them very easy to learn and use, and very intuitive for a lot of younger operators,” he said.

In construction, robotics and labor saving technology can make a difference in the field and the back office alike.

“Software exists that helps decision-makers manage billing, invoicing, and jobsite progress against contractual agreements and budget projections,” said Lengienza, whose company, Procore, offers construction management software for intelligent risk management, from preconstruction to closeout. “By integrating the business side of things with what’s happening in the field, firms are able to control costs, maintain schedules, and elevate productivity,” he said. The net result is that business can do more with less.”

Perhaps nowhere is the impact felt more than in the field, where smart machines are helping novice workers perform at near-veteran proficiency. This is due in part to the evolution of machine control technology, automating functionality according to specific site designs.

Machines equipped with advanced technology features, such as sensors, monitors, and autonomous controls, are able to read digital design information and perform operations within extremely tight tolerances. Operators in the cab no longer have to study schematics on paper or be trained for precision work to get precise outcomes. Even novice operators can produce professional results.  BUILT Robotics

BUILT Robotics

Using remote operation capabilities, an operator doesn’t even need to be in the cab to effect superior results. From the comfort of a command center, they can remotely guide a load bucket through an earth pile and come clear with a precise fill every time. The economy of effort is maximized, while material resources are spared.

The Advantages of Remote Operation and Automation

The use cases for remote operation and automation technology, including robotics, are still emerging. But wherever operator safety, training, or morale is concerned, you’ll likely find a home for technology in your organization.

Built Robotics sells a fully autonomous robotic pile driver, the RPD 35, that performs four functions with a single robot. A team of two can manage multiple robots, marking GPS ground points, dragging piles to the location, driving the piles, then reporting the data. It could take 10 to 15 crew members to perform the same tasks without automation.

Likewise, FORT Robotics recently helped a Georgia-based landscaping startup beat the labor shortage using software and retrofit kits to transform existing zero-turn mowers into self-propelled machines. The mowers not only relieved the physical strain workers experienced driving the machines in all types of weather, but also lowered cost, increased productivity, and automated the tedious work so that crew members could focus on more valuable tasks.

Out-of-the-box applications also abound as users experiment with the possibilities. For instance, augmented and virtual reality are making it possible for operators to view site plans imposed directly over raw land. Virtual display screens built into headsets indicate exact markings, guiding earth movement and site preparation.

Onboard AI can be programmed to coach new hires on certain machine functionalities, accelerating time-to-productivity and freeing highly paid trainers to focus on other value-added work.

“One of our stevedore customers started using our automated cranes to help unload material from ships midstream, protecting workers from having to move containers onboard or at the dock,” said Pumklin. “It was all done using robots, remotely controlled by an operator sitting in a Cat Command station, managing four bots at a time. That’s a 4-to-1 ratio. That’s hard to beat.”

How to Get Into the Game

As the labor shortage lingers, more competitors are choosing to adopt remote operation and automation technology. Fortunately, the process is easier than you might think. Retrofit kits and software upgrades are widely available to meet you where you are in your journey. The best advice is to talk to equipment vendors and assess your specific needs.

“Ask your people what they need to be more effective, then examine those processes before you invest,” said Lengieza, who cautions that technology is not always a panacea. “You can’t just buy cool stuff and expect to move the needle. Think in terms of ROI. If you can reduce your headcount, time or cost on a job by 50%, you’re probably looking in the right place.”

As well, consider the impact technology might have on your current staff. Educate them on the advantages of technology and assure them that you’re not out to replace them, but to improve their work life. If you integrate change management principles into your plan, you can increase acceptance and accelerate adoption.

“I like to think of it this way,” says Pumklin from Caterpillar. “If you can operate a machine remotely from home as you recover from an injury, that’s a paycheck you can cash.”

That’s a quality of life investment.