Coming in on time and under budget – that's the dream, and by using microgrid technology to power a construction project with clean energy, that can also be the reality. Driven by a need to curb growing energy costs, paired with a sharp increase in the market demand for accelerated sustainability performance, contractors and customers alike are increasingly shifting to use clean energy to power jobsites. And an added bonus? Project schedules have been shortened due to the easy installation that modular, off-grid microgrids offer.

A distributed energy microgrid is like a small power plant that produces renewable energy on site. Traditional electricity sources commonly used to power jobsites (e.g., local utilities and generators) lack the advantages that microgrid technology offers.

Using microgrids can:

- Provide rapid access to power

- Minimize greenhouse gas emissions into the environment

- Save money on energy costs

- Offer real-time energy performance monitoring

- Create an uninterruptible power supply

Reduced Timelines

Obviously, construction sites need electrical power to support the work being done by contractors and subcontractors. Traditionally, sites obtain temporary power straight from the utility grid. This can be time-consuming and expensive. When all is said and done, the process can sometimes take several months to coordinate and install the infrastructure needed to supply electricity.

Powering a jobsite using microgrid technology drastically reduces the time it takes to bring a construction project online, reducing the overall construction schedule.

Agropur, one of the largest dairy cooperatives in North America, was able to take advantage of microgrid technology when building a new 210,000-sq.-ft. cheese production facility in Little Chute, WI.

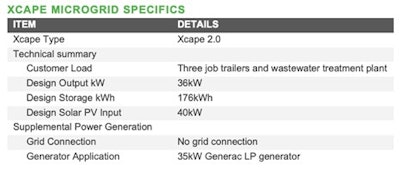

Agropur enlisted the help of EnTech Solutions, a full-service clean energy solutions provider, to assess their energy needs and engineer a solution that could be easily and quickly installed. EnTech Solutions installed two Xcape off-grid microgrids that harvest 40 kW of solar energy and provide 160 kWh of battery storage to power three job trailers on the construction site. The system includes energy storage along with a low-carbon propane generator to provide power when the sun isn’t shining.

Instead of dealing with any delays due to utility installation at the Agropur site, the EnTech microgrid was operational within two weeks.

“The EnTech Solutions microgrid provided an attractive alternative solution to a long and costly power cable installation for the southern part of the construction site,” Joe Dikeman, Agropur’s regional automation manager, explained. “There was minimal install and setup to be able to power the construction trailer and building during the construction phase.”

Agropur's sustainability goals and its commitment to the U.S. Dairy Industry's goal of net-zero emissions by 2050 or sooner was a key motivation in their utilization of clean energy microgrid technology. At the end of the year-long project, EnTech estimates that the Xcape microgrid solution will have reduced Agropur's CO2 emissions by 77,494 lbs., equivalent to the amount of CO2 captured by 43.1 acres of U.S. forests.