The Project Minotaur DL550B compact dozer/loader fills two roles: it’s a replacement dozer for the discontinued Case 450C dozer and can operate as the largest Case compact track loader.

“We really used the specs of the original 450 [dozer] as kind of a benchmark to line up [the DL550B] against,” says Brady Lewis, program manager for Project Minotaur at Case Construction Equipment. The new machine outweighs the dozer by more than 50%, its steel tracks generate about the same pushing force and the DL550B blade is a little bigger than what was on the 450.

“Coming from the CTL heritage makes structural differences to the machine, but really that was our goal: to provide customers a machine that could do that small dozing job that used to be served by the 450.”

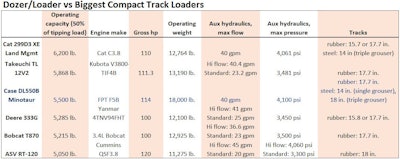

It’s no coincidence that the DL550B’s 1,000 lb. of additional rated operating capacity over the TVL450, Case’s largest compact track loader, gives it 5,500 lb. of rated capacity. That capacity puts it in the thick of competition with Caterpillar, Takeuchi, Deere, Bobcat and ASV at the large end of CTLs on the market today.

“Even if you set all of its dozer capabilities aside and say ‘That’s not for me,’ you still have a very compelling compact track loader,” says Lewis. With a 1 ¼- cu.-yd. bucket, it can bring as much to the truck in one pass as many loaders take in two.

The dozer/loader’s rated operating capacity (at 50% of tipping load) is about 11% under the industry’s heaviest-lifting compact track loader, the Cat 299D3 XE Land Management. (Coincidentally, this Cat is the only other CTL in the size class with a steel-track option.) And Takeuchi’s TL 12V2 will handle about 6% more rated capacity.

But none of the competitors outweighs the DL550B. Case’s preproduction specs list its operating weight at 18,000 lb. As a dozer/loader, that weight includes its 2,300-lb. C-frame and dozer blade. It’s necessary to drop off the dozer (Lewis says it takes about 30 seconds . . . 90 seconds to hook back up) to use the loader. The dozer/loader’s bucket weighs 1,000 lb. So even at a loader-comparison weight of 16,700 lb., the DL550B is nearly 27% heavier than the next-heaviest competition (the Takeuchi).

With that extra weight the DL550B will require a one-ton pickup and a commercial driver’s license to transport.

The Case hybrid machine offers a ripper attachment on the rear, but it’s balanced to operate with that ripper’s weight. Buyers who opt out of the ripper, get a machine with counterweights to make up the attachment’s weight.

Lewis attributes the DL550B’s operating weight to additional steel reinforcing the machine’s structures.

“In our development, we’ve been trying to design the machine to do 100% of both [loading and dozing work]. They do put different loading into the structures, and it’s been one of our focuses to make sure it can handle the worst-case dozing job and also handle the worst-case compact track loader jobs.

“Another thing that’s hard to point out standing around the machine is the control piece of it,” Lewis says. He acknowledges that you certainly can doze with a 6-way dozer attachment on a loader, “but it’s not very intuitive. A lot of them use one set of hydraulic lines, and so to do a multifunction operation you have to do something else – kind of like hitting the shift key on your keyboard to get a capital A. You have to push a button to run the angle, and another button to run the tilt on the blade.

“An area where we’ve focused on the DL550B is to make the control system operate like a dozer. So we’ve got two sets of hydraulic lines going to the different circuits and we have used a lot of our control system logic from our dozer product line. The intent is so a customer who his running a dozer can hop in this machine and it feels and responds the way that they are accustomed to.”

The difference in standard drive patterns between Case dozers and CTLs shows up when the operator tries to turn in reverse. Case takes advantage of dozer operators’ experience by setting up the DL550B with a user choice of either standard dozer or loader control patterns.

Buyers with need for a lot of small dozing in addition to their loader work will be most interested, of course in the dozer/loader’s frame-mounted dozer.

“Case sells 6-way attachments for our CTL lineup, and there’s a place for those,” says Lewis. “But with the frame-mounted C frame that you get on the DL550B, your real advantage is that all of that force [of dozing] is going into your machine’s frame rather than the loader arms.”

The loader stops on the front of a CTL’s frame transfer horizontal load into the frame when the loader arms are all the way down, but “it may be difficult to keep arms down against the stops. Because as soon as you start trying to raise the blade, you lift the arms off the stops.”

The DL550B’s loader arms raise and lower the blade, too, but through a four-bar linkage that transfers all of the horizontal dozing force at all blade heights into the beams that are pinned directly to the loader frame. “There’s no way for that force to get transferred into your loader arms,” says Lewis.

“Dozing a very small percentage of the time with an attachment is probably not a problem; lift arms are designed to handle pushing. But if you’re trying to do really heavy dozing and putting a lot of force into that blade, and you do it a significant percentage of your duty cycle, [the DL550B] will definitely reap rewards over the life of the machine.”

Case’s DL550B is expected to come with a 96-in. 6-way PAT dozer. Some makers of competitively sized compact track loaders brand a 91- or 96-in. PAT dozer attachment, and there are 91- and 96-in. PAT attachments available in the aftermarket.

Case’s DL550B is expected to come with a 96-in. 6-way PAT dozer. Some makers of competitively sized compact track loaders brand a 91- or 96-in. PAT dozer attachment, and there are 91- and 96-in. PAT attachments available in the aftermarket.