Efficient fleet operation is aided by planned preventive maintenance. An integral part of that process should be monitoring component wear through oil analysis.

"Oil analysis is an effective tool that can help you monitor the condition of your engine," says Dan Arcy, OEM technical manager, Shell Lubricants. "The knowledge gained from a consistent oil analysis program can assist you in optimizing your oil drain interval, help increase equipment reliability, minimize unscheduled downtime and more precisely track operating efficiency and maintenance practices. The combination of all this contributes to helping lower total operating costs."

Diagnostic oil analysis alerts maintenance personnel to potential hidden or emerging problems or failures, says Will Willis, Jr., president and CEO, On-Site Analysis, a company that offers technologies that interpret sophisticated technical measurements into simple-to-understand diagnostic statements. "That means you can do preventive maintenance repairs while they're small, rather than wait for costly catastrophic failures," he says. "Less failure translates to fewer tows and breakdowns and less vehicle downtime."

Sampling Basics

Virtually all oils used in equipment can be tested, but the majority of tests are engine oil samples, followed by transmission, driveline or gear applications and hydraulics, notes Mark Betner, heavy duty product manager, Citgo Lubricants.

Regular sampling and analysis of these fluids establishes a baseline of normal wear and can help indicate when abnormal wear or contamination is occurring. To ensure consistent results, Arcy recommends taking samples in the same manner each time. For example, he notes, "Withdrawing [engine] oil through the dipstick opening is a good way to take the sample. This can reduce the chance of outside dirt or contaminants getting into the sample."

All paperwork accompanying each sample should be as complete as possible. This information is critical to providing a complete and accurate analysis report. Be sure to note if any oil was added between oil drains and the type used.

Once a lab receives an oil sample, it typically takes 24 to 72 hours before the data is ready for reporting. For optimal benefit, samples should be sent in promptly after they are taken.

"It is very important that the oil analysis user realizes the longer it takes to get the sample to the lab, the longer it takes to get data back," Betner comments. "It is not uncommon for samples to sit around shops waiting to accumulate several samples so that a bundle can be shipped to save on shipping costs. But in the long run, the value of the testing is lost due to this type of delay."

Fluid "Forensics"

Metallic trace particles from wear, products of the combustion process and any externally generated contaminants will all become trapped in oil as it circulates through the engine or other key systems. Consequently, the oil becomes a working history of these components.

By identifying and measuring these impurities, you can get an indication of wear rates and any excessive contamination. "Used oil samples can tell you if contaminants such as water, coolant, fuel or dirt are getting into the oil, indicating a head gasket leak, leaking fuel injector or other problems," says Arcy. "Spectrochemical analysis detects the presence of wear metals in the oil. Unusually high amounts could be a sign of abnormal wear."

Spectrochemical analysis is an analytical technique in which an oil sample is heated to a high temperature, usually in a carbon arc, to produce emission lines whose intensities are proportional to the abundance of elements present.

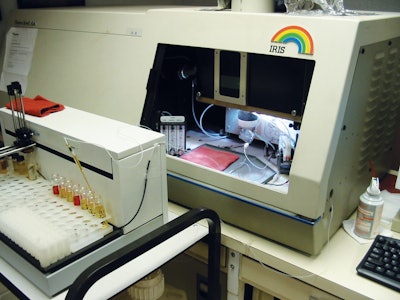

Using computerized test equipment, typically a very small amount of used oil sample is energized (burned in an electric arc), explains Jeff Wohlwend with OilCheckUp, a custom manufacturer and distributor of filtration test media and multi-fluid test strips. This results in a wavelength, or color, of light that is compared against the standard acceptable levels of wear metals or contaminants. These results reflect the concentration of all dissolved wear metals, both from the component and the fluid.

This lab analysis provides a quantitative evaluation of a fluid's composition and condition, including viscosity, total sludge content, particle count, glycol contamination, fuel dilution, fuel soot level, grime and additive package depletion, says Ron McElroy, president and chief technology officer of Fluid Rx, a company that does instant lubricant diagnostics.

More specialized tests can be performed on an oil sample, as well. There are oil analysis services that offer upgrades or additional testing depending on the application, operating conditions and maintenance goals, says Betner.

Additional tests, or premium used oil analysis, can help in determining the optimum oil drain intervals or identify specific problems, Arcy adds.

Gauging Results

Fluid analysis programs differ in many aspects, including tests available, interpretations and reports, turnaround time, price and more. So adequate time and effort needs to be invested in order to choose the program that best serves your needs.

For example, some fluid suppliers offer their own analysis programs with the ability to gauge your fleet's performance against industry benchmarks.

Take Citgo's LubeAlert Oil Analysis Program, an electronic analysis program for heavy-duty oils, gas engine oils and special products, including water-based hydraulic fluids. (Tests can also be customized for oils not falling into standard categories.) The program monitors more than 160,000 engines and 1,700 fleets of all makes and models, and has a database documenting trends on virtually all types of diesel engines. The Summary Analysis feature creates a "maintenance report card" that allows management to rate maintenance facilities, target problem areas and evaluate engine makes and models.

The Shell LubeAnalyst program offers easy-to-use software that enables users to view results, track test results and view offline management information. Late last year, Shell Lubricants revamped the program to better help customers improve equipment and vehicle reliability, while reducing maintenance costs. This includes an online user interface that offers a worldwide sample historic database and failure trends on various types of equipment and engine types.

Reports show results from previous tests, graphs on oil properties, wear and contamination. Comments about any possible trouble areas and any recommended actions that may need to be taken are also provided.

Once results from an oil analysis are received, it's important that the report be fully understood. Consult with the oil analysis provider if you're unsure of anything.

"Newer engines tend to have some anomalies that can produce false critical reports," Betner says. "Knowing when and why these situations occur can avoid loss of confidence in the reporting and, more importantly, when and how to react to the data. Generally, oil contamination is the No. 1 cause of lubrication-related failures, so critical reports involving coolant, dirt, fuel and, in some cases, soot contamination, should get the full attention of the user."

If a sample indicates a critical issue, the customer is contacted by phone or fax by the laboratory to communicate the sample results, says Arcy.

Opportunity for Instant Feedback

An inconvenience of lab analysis is the turnaround time required from the time a sample is taken until results are available for evaluation.

"For instance, glycol contamination and/or fuel dilution, which are two of the main killers of diesel engines, can begin to manifest shortly after sampling cycles," McElroy says. "Component damage or catastrophic failure may occur before the next sampling cycle and lab analysis is performed. Instant lubricant diagnostics is the stopgap between lab analysis cycles to catch these problems and prevent costly repairs and equipment downtime."

Compared to the lab process, instant analysis offers a low-cost, quick and simple to understand method for determining a fluid's condition at regular intervals on the spot, says Wohlwend.

Instant analysis kits are simple to use, and no tools or special knowledge is needed. Simply follow the instructions included with each kit, says McElroy.

All modern lubricants contain additives that inhibit breakdown, he explains. As these additives are depleted, sludge forms. Instant analysis kits utilize a chromatographic process to provide a measure of additive depletion and the level of sludge or debris in a lubricant.

The chromatography technique indicates the total amount of wear metals and particle contaminants based on particle size (micron rating), Wohlwend explains, with visual and comparative results to a new fluid sample of a preferred brand.

The process basically works as follows: A drop of the sample oil/lubricant is placed on a thin layer of absorbent filter paper or specialized media. As the fluid test specimen percolates through the paper/media, bands and/or zones of different colors, densities and even unwanted wear metals and debris form a chromatogram — a series of color bands or color graph.

Changes in the appearance of the zones or bands are a clear indication that something in the lubricant has changed. A closer look at the zones, their unique formation and the debris fields contained therein may indicate an increased level of contaminants, additive depletion, breakdown of fluid, viscosity changes, etc.

The instant analysis chromatography technique is not limited to any type of fluid, Wohlwend points out.

McElroy notes that it can handle brake fluids, power steering fluid, automatic and manual transmission fluids, gear oils, crankcase oil, synthetic and petroleum-based fluids and oils. There is even technology that provides diagnostics for all formulations of antifreeze and coolants.

David Kolman is the editor of Fleet Maintenance magazine (www.vehicleservicepros.com).