Removing particles — dust, dirt, leaves, etc. — from the air that flows through the engine prevents premature wear and fouling of components such as turbochargers, charged air coolers, cylinder walls, piston rings and bearings, to name a few. Air filter manufacturers continue to research and develop new technologies to increase dirt-holding capacity and particle removal efficiency, and reduce air flow restriction for improved engine performance.

Most diesel engine manufacturers require air filters to be at least 99.9% efficient at removing particulate, says Jon Wake, global business development manager, Air and CCV Filtration Systems at Parker Hannifin Corp.’s Racor Division. To determine efficiency, ISO 5011 and SAE J726C state that manufacturers measure how much particulate the filter collects.

Advances in Filtration Media

The type of filtration media used in an air filter is the first step to ensuring an efficient filter design. One method for improving filter efficiency is through the use of nanofiber technology. Nanofiber has an ultra-fine fiber diameter that can be added to filtration media, typically made from paper-like materials, to enhance efficiency of the media while still keeping it open for higher air flow.

The fibers used in Baldwin Filters’ ProTura nanofiber technology, for example, have an average physical size of 90 nanometers (nm). Utilized in many of the company’s heavy-duty air filters, the nanofibers enable the filtration media to capture contaminants at the submicron level. “The advantage [of nanofiber technology] is a higher initial efficiency and a lower pressure drop, which equates to a more efficient filter and a longer service life,” says Rich Palmer, vice president, Original Equipment Sales, Baldwin Filters.

New filtration media developments have also been brought about by the implementation of Tier 4 engines. Palmer says two of the most significant changes are increased air flow and higher operating temperatures. “For air flow, requirements of most engines have increased significantly, some by 20% or more,” he says.

Meanwhile, increased underhood temperatures have necessitated the use of new materials for filtration media that can withstand the higher temperatures.

Andrew Shepard, director of Global Market Management, Hollingsworth & Vose, says the heavy-duty equipment industry has begun adopting some of the European standards for media smolder resistance (SR) and flame retardancy (FR) to improve vehicle safety. He notes that not all FR and SR industry additives are the same. It is important to ensure the additives used in the media will continue to function after getting wet, especially for air filters that typically ingest rain or snow.

Palmer adds that this type of media is typically found in forklifts operating in warehouses because of the potential backfiring that could occur and cause an air filter element to catch on fire. Underground mining applications benefit from the use of this type of media, as well, when working in hazardous environments where there is the potential for combustion and ignition of gases in an enclosed area.

Benefits of Precleaners

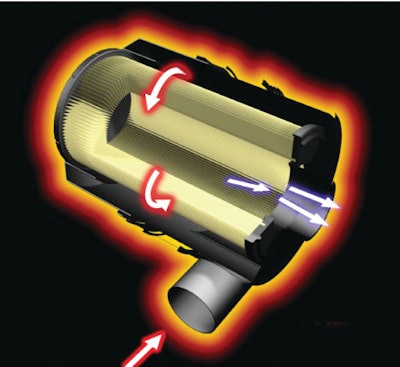

Many filters utilize precleaners as an additional means of removing contaminants from air flow. While air filters physically filter and trap incoming contaminants in the air, precleaners separate and eject harmful contaminants using inertial separation. A series of vanes within the precleaner cause the air flow to spin as it passes through the vanes. As the air spins, dust particles and other contaminants are forced to the outer edges of a vane and ejected into the environment. The cleaner air then flows on to the air filter where any remaining particulates will be filtered out.

“As a result, precleaners require little to no servicing, as they do not collect and store [contaminants],” says Mike Anderson, product director, Air Business Unit, Donaldson Company. Typically placed at the beginning of an air induction system, a precleaner can be integrated into an air filter or act as a separate component.

According to John Gaither, director of Heavy-duty Engineering, Luber-finer, precleaners are able to remove the majority of the bigger particles (usually 30 micron or larger) found in the air flow. “In conditions with high airborne dust concentrations, a precleaner will remove the most massive particles before they have a chance to build up on the air filter,” he says. “Keeping [larger particles] away from the air filter increases service intervals and overall system efficiency.”

Precleaners are able to separate and remove 75% to 96% of incoming dust and debris from the air, says Anderson. Because they can remove so much of the initial particulate that can get trapped in air flows, precleaners have been shown to increase filter life up to 20 times. A precleaner’s ability to capture higher amounts of large particulate pieces makes it well suited for use in off-highway equipment working in high-dust environments.

The greater a precleaner’s efficiency, Anderson adds, the smaller an air filter can be, which is especially important for vehicles with space limitations.

Tighter Space Constraints

One of the biggest challenges for air filter manufacturers is creating a filter that will fit into the ever-tightening space allotments of vehicles and equipment. In the past, the air filter was simply mounted to the top of the hood or close to where the engine was located. But with today’s more streamlined designs, filters are being placed under the hood where space is at premium.

“It’s always a challenge to be able to make an air cleaner smaller, yet still accommodate the high air flow rates required by the engines,” says Wake.

The implementation of Tier 4 engine systems has reduced available space due to the larger cooling and exhaust aftertreatment systems the engines require. The space constraints have prompted air filter manufacturers to focus their research and development efforts on creating technologies that can fit into the smaller machine footprints while still providing the same, or better, filtration performance.

For its PowerCore filtration technology, Donaldson was able to design compact yet efficient air filters that can reduce the air intake system size by 60%, says Anderson.

Future Trends

The use of plastic housings for filters is becoming more prominent within the filtration industry. Both Wake and Anderson say the shift away from metal housings is due to the weight and cost savings plastic can provide.

However, the choice of housing material depends on the application in which the filter will be used. While a plastic housing can offer weight savings, a metal housing can be more beneficial for severe-duty applications, where the amount of vibration could affect filter performance if it is not protected by a more durable housing.

Filtration media and how it’s packaged will also be a focus for future research and development efforts. Wake says some companies are moving away from traditional pleated filter media packaging — designed to provide more filter media area — to a fluted arrangement. A fluted design looks similar to a honeycomb, and allows air to flow straight through the filter from one end to the other. “It’s [a way to] package the filter media into the housing to optimize the air flow and the collection of dust, and try to reduce the filter restriction itself... in the smallest package possible,” says Wake.

Overall, improved efficiency and dirt-holding capacity will continue to be the key drivers for engine air filter design now, and far into the future, to ensure optimal engine and vehicle performance.