When using oil additives, more is not always better. As more additive is blended into the oil, sometimes there isn’t any more benefit gained, and at times the performance actually deteriorates. In other cases, the performance of the additive doesn’t improve, but the duration of service does improve.

It’s crucial to understand the role of additives and their function(s) within the lubricant. Additives are organic or inorganic compounds dissolved or suspended as solids in oil. They typically range between 0.1% to 30% of the oil volume, depending on the machine.

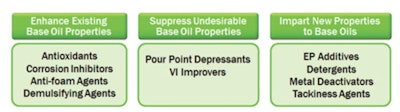

Additives have three basic roles:

- Enhance existing base oil properties with antioxidants, corrosion inhibitors, anti-foam agents and demulsifying agents.

- Suppress undesirable base oil properties with pour-point depressants and viscosity index (VI) improvers.

- Impart new properties to base oils with extreme pressure (EP) additives, detergents, metal deactivators and tackiness agents.

Read the entire "The Critical Role of Additives in Lubrication" article from Noria's Machinery Lubrication.