The compact equipment industry is experiencing a transformative shift as electrification becomes a cornerstone power source. More original equipment manufacturers (OEMs) are exploring the benefits of converting gas-powered equipment toward battery power. Electric equipment offers several compelling advantages including enhanced sustainability and efficiency, reduced operating costs and maintenance and quiet, emissions-free operation.

However, there is a lot to consider when it comes to electrification and navigating the process of converting gas-powered equipment to battery power. Electrification is more than just replacing a traditional internal combustion engine with an electric power source such as a battery. It also involves integrating necessary components to create a comprehensive battery system that includes components such as motors and motor controllers. As industries move toward more sustainable technologies, electrification is becoming a crucial strategy for OEMs to remain competitive and meet regulatory standards.

Electrical engineering expertise needed

For OEMs, a different skill set is needed in engineering to develop high-performing electric equipment that gives users the right experience. Electrified equipment offers many capabilities, so OEMs need to fully understand what the interconnected components of a battery system can do. This will unlock the benefits battery power can offer to make work easier, safer and more efficient.

From evaluating battery options and understanding the range and runtime of equipment to determining efficiency gains and integrating the battery system into equipment, there is a lot that goes into making the switch to electric power. Navigating these complexities can be challenging, especially for small- and mid-sized OEMs. Partnering with electrification experts can help with offering engineering support and standardized solutions to streamline the electrification process.

By leveraging extensive, first-hand knowledge and experience, power application experts can help OEMs overcome technical challenges such as power density, weight distribution and thermal management. A good partner also will help ensure compliance with regulatory standards and address safety concerns that are paramount in new technology adoption.

Let’s explore the electrification process and what OEMs should expect when navigating the electrification journey.

Understanding power needs

The journey to electrification begins with meticulous preparation and a deep understanding of the application's existing power needs. One of the initial steps is creating a load profile, which involves assessing the equipment's power needs and usage patterns. Understanding the load profile is essential for determining the appropriate battery size and specifications. Factors such as capacity, voltage and battery chemistry play a critical role in this decision-making process, ensuring the selected battery meets the equipment’s performance requirements.

Creating an accurate load profile requires a detailed analysis of the equipment's operational cycles. This includes identifying peak power demands, average usage patterns and potential energy-saving opportunities. Equipment used intermittently throughout the day will have different power requirements than machines that are continuously running. By accurately mapping these needs, OEMs can select a battery that provides optimal performance without oversizing or undersizing the power source.

Once the load profile is established, the next step is proper battery sizing and specification.

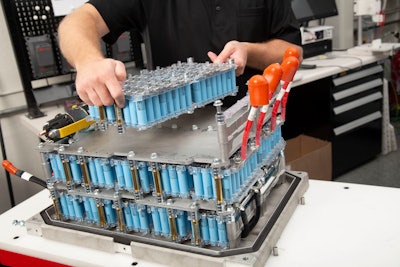

Designing the battery system

Battery technology has splintered into several different categories as it has evolved over the years. Various chemistries such as Lithium-Ion, nickel-metal hydride and lead acid have their own advantages and limitations. Lithium-Ion batteries, for example, are known for their high energy density and long cycle life, making them ideal for compact equipment. However, the choice of battery also depends on factors like cost, weight and environmental conditions. OEMs must weigh these considerations to select the most suitable battery for their specific applications.

Engineering support from experts extends beyond just providing a battery to replace an engine. It includes comprehensive integration support, ensuring the battery system is integrated into the existing equipment design. This involves modifying equipment to accommodate the battery, optimizing the placement of components for balance and stability and integrating power management systems that regulate battery usage and charging.

Engineering support from experts includes comprehensive integration support, ensuring the battery system is integrated into the existing equipment design.Briggs & Stratton

Engineering support from experts includes comprehensive integration support, ensuring the battery system is integrated into the existing equipment design.Briggs & Stratton

Battery integration and application testing

Integration and application testing are crucial stages in the electrification journey. Seamless integration of battery power into existing equipment designs requires careful planning and execution. Application testing involves rigorous assessments under various operating conditions to ensure the equipment's performance meets industry standards. This includes testing for durability, efficiency and safety.

For example, compact equipment used in construction must be able to withstand harsh environments, heavy loads and continuous operation. Through extensive testing, OEMs can identify potential issues, make necessary adjustments and ensure that the electrified equipment performs reliably in real-world scenarios. After the equipment has proven itself in initial trials, OEMs often will put the machine through its paces with field testing to get customer feedback on its performance and runtime.

The process of converting gas-powered equipment to battery power is multifaceted, involving careful planning, technical expertise and rigorous testing. With the support of electrification experts, OEMs can navigate this journey and help ensure a successful transition to electric power as they look to offer a competitive lineup of gas and electric equipment offerings for whatever a customer may be looking for.

Looking ahead to the future

As the market evolves, OEMs that embrace electrification for their vehicles will be well-positioned to meet the growing demand for zero-emission solutions. The adoption of electric power is not just a trend, but a strategic move towards a more sustainable and efficient future. By staying ahead of technological advancements and leveraging the expertise of electrification specialists, OEMs can ensure a smooth transition to electrification while capitalizing on the opportunity to offer more power choices to their customers.

Stephen Avery is engineering manager — battery applications at Briggs & Stratton.