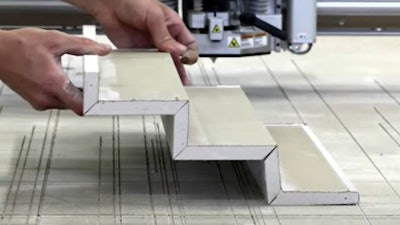

Professional Drywall Construction, Inc. (PDC), a commercial drywall company headquartered in Springfield, Mass., has created a unique drywall method called Origami.

This custom cut drywall uses a combination of gypsum, wood, plastic and even cement board to complete intricate and complex assemblies while keeping costs down.

PDC

PDC

“We pre-fabricate profiles in our shop, reducing on-site installation time and increasing the overall appearance as corners and other profiles are installed in one piece,” says Ron Perry, president and co-owner of PDC. “We can easily and accurately duplicate multiple cuts, make finished returns and perfect corners at any angle, not just 90 degrees. This makes corners more durable and easily repaired. The process gives our customers design flexibility never thought possible.”

Watch the Origami drywall method in action:

Origami drywall allows for the creation of true right angles at corners, and complex shapes and curves.

The intricate cuts that allow the drywall to bend and mold to any shape are all made in-house by masters of their craft and then installed in one piece at job sites.

The process saves labor costs by cutting down on time spent on the jobsite performing installations. It also helps to enforce vulnerable areas, making quick repairs possible.

“Our Origami installations are quite durable,” Perry says. “Fixing a traditional drywall corner that has been dented or damaged can be time-consuming and expensive. While our corners can be dented, the damage is much less severe, and repairs can be accomplished by a maintenance worker with joint compound.”