There has been a major shift in the construction industry, with manufacturers making a push toward more electric, battery-powered equipment in order to promote greener, cleaner, and more efficient operation. This electrification trend hasn’t missed the engine manufacturers, who have had to deal with a host of expanded fuel options and stringent emissions regulations that require new and evolved technologies.

The EU Stage V is the most stringent regulation to date for the off-highway equipment industry, while the U.S. is currently meeting Tier 4 Final emissions standards. And with new advanced engine technology, comes new strategies.

These factors contribute to equipment users, business owners, and rental houses redefining maintenance and efficiencies within their operations for proper engine care. And while engines have evolved over time, so have the technologies available to help monitor engine performance and manage proper service schedules.

We spoke to some of the industry’s top engine manufacturers, including the engineering and technical service teams at Hatz, Perkins Service Training Manager, Andy Miller, and Steve Nendick, marketing and communication director at Cummins, to learn more about their tips for engine maintenance, what to pay attention to in terms of cooling systems, the different fuel types, and more.

Q: What are your top five service tips for larger diesel engines to maintain peak performance year-round?

Hatz:

- Precisely follow the maintenance schedule in the engine’s owner’s manual (including daily and weekly checks) and adjust the intervals as necessary if the engine is in harsh or unusual conditions. For example, if the engine is in a dusty environment, keep a close eye on the air filter. It may need to be changed more often than required by the engine manufacturer.

- Be careful when power washing the equipment and engine. Newer engines have a lot more electronic components that may be damaged by high velocity water.

- Make sure you are monitoring your diesel particulate filter (DPF) status and performing the requested regeneration. Don’t just keep overriding the warnings for a passive regeneration or your engine may stop running during a shift. If you cannot run a regeneration immediately upon the first warning, make sure someone runs an active regeneration at the end of the day.

- If the engine is seeing a lot of idle time or low-load conditions, make sure you run the engine at full load for at least 30 minutes at the end of a shift to ensure the diesel oxidation catalyst (DOC) is reaching the appropriate burn out temperatures.

- Pay close attention to any error codes, or DTCs, and address them immediately by performing the proper maintenance or repair. It greatly helps to have the manufacturer specific diagnostic tool and factory service training.

Cummins:

- Use the correct parts. Cummins genuine parts are now available on SmartEquip, making it easier to ensure you have the right parts for your engine to maintain your machine’s performance and productivity.

- Following recommended maintenance schedules is critical to ensure that equipment provides optimum performance. Poorly maintained machines will use more fuel for the same amount of work than a well-maintained one. Preventive maintenance saves fuel costs, major repairs in the long-term, and maximizes the productivity and life of the engine.

- Use the correct fuel, oil, and diesel exhaust fluid (DEF). Following the manufacturer’s recommendations to ensure the correct fluids are used and kept at the required levels will ensure the performance of the machine stays within its specification. Additional checks on tire air pressure and air filter cleanliness are also important for optimal operation and fuel efficiency.

- Engine filters are becoming more technologically advanced to prevent harmful contaminants affecting the engine. They must meet the manufacturer’s approved standards to provide the quality of filtration necessary to achieve the engine's design life. If other brands are substituted, there is a risk that the service intervals will be reduced, and engine damage could occur.

- Use Quickserve on-line. The website, quickserve.cummins.com, gives you access to all the service information for your Cummins engine simply by entering your serial number.

Perkins:

- Engine oil sampling, change intervals, and oil grades. As larger diesels tend to have higher load factors and operate longer hours, keeping the engine oil healthy is critical. Scheduled Oil Sampling is highly recommended to be able to pinpoint when the oil is degrading to be able to change it at the right time. It is also important to select the correct grade and viscosity based on the conditions the engine will operate in. Over the least 10 years or so, diesel engine oil has gone through several upgrades, so it’s important to make sure you're using the correct formulation for your engine. Always refer to manufacturer guidelines.

- Coolant condition and system performance. An overheated engine can lead to seal failures and damaged components such as cylinder heads, turbos, and manifolds. As larger engines with high load factors put high demand on the coolant and cooling system, it's critical to make sure these are operating flawlessly. Simple things such as ensuring there is enough airflow across the radiator or heat exchanger can make all the difference. Also make sure they are kept clean from dust and dirt buildup, and that the cooling fins are not damaged. Coolant formulation is also important as certain engines may need additional additives to ensure optimal performance.

- Fuel cleanliness and filtration. Not maintaining the fuel system with a high regard for cleanliness can lead to major expenses down the road. Today’s engines are equipped with highly sophisticated fuel systems with extremely low tolerances inside the fuel pumps and injectors used to move fuel through the system. Through all aspects of the fuel filling process, make sure surfaces, containers, and transfer pumps are clean and void of any other types of fluids. Ensure all fuel filters are replaced at the same time, and that OEM recommended filters are used to ensure best possible protection.

- Seasonal preparedness. If the engine is used year-round but is in an environment where the ambient temperatures can change dramatically between seasons, make sure the engine is prepared for that change. In the fall going into winter, make sure any cold weather startup aids are functioning such as block heaters, air inlet heaters, or ether aid systems. If alternate diesel blend is needed for winter, make sure it’s getting switched over early enough that no fuel gelling issues will impact operations in the early stages of winter. Going into the summer months, it's important to ensure the cooling system can deal with the higher temps. If the cooling system airflow was reduced in the winter to address overcooling, has it been returned to normal for the higher temps that could lead to overheating?

- DEF handling and cleanliness. Most engines today in North America and Europe are equipped with aftertreatment systems that utilized DEF. Ensure that the utmost attention is given to cleanliness when filling the DEF tank. Make sure tank fill necks are clean, containers are clean, and not contaminated with other fluids, etc. DEF needs to be stored out of direct sunlight and in an environment that doesn’t exceed 95°F to ensure it performs as desired.

Q: New advanced engines and cooling systems are changing cooling system maintenance requirements. What should rental houses pay attention to when it comes to cooling systems?

Hatz: The most important thing to make sure of is that you’re using a factory recommended coolant. Every engine manufacturer uses a different exhaust gas recirculation (EGR) cooler made from various materials, which interact with the chemicals in a lot of the standard coolants and cause issues with the EGR portion of the exhaust aftertreatment. Don’t assume that just because one engine manufacturer approves a specific coolant, that it’s the same requirement for all engines. If possible, get the actual chemical requirements for the coolant itself; for example, Hatz requires coolant to be Nitrate- and Nitrite-free.

Cummins: Off-highway equipment operates in a wide variety of climates, so it’s important that the cooling system is maintained to ensure the engine continues to operate as it should. Regular visible checks should be made to:

- Check for damaged hoses, and loose or damaged hose clamps.

- Check the radiator for leaks, damage, and buildup of dirt.

- Check belts, pulleys, and tensioners for wear and tear.

- Check the coolant level and top up as needed.

To ensure proper additive levels and coolant pH, coolant test strips are an easy way to eliminate guesswork and validate that the cooling system is operating at peak performance. Test strip recommendations are intended to prevent maintenance and engine problems from causing progressive, severe damage.

Each category of coolants has a recommended test interval: OAT coolants – 1,000,000 miles, 20,000 hours of useful life under normal operating conditions, or one year; Hybrid coolants – 150,000 miles, 4,000 hours, or one year; and conventional coolants, which are every oil drain interval or one year. Operators should check their machine’s service manual to find the correct coolant type they need.

If the engine is used year-round but is in an environment where the ambient temperatures can change dramatically between seasons, make sure the engine is prepared for that change.Perkins

If the engine is used year-round but is in an environment where the ambient temperatures can change dramatically between seasons, make sure the engine is prepared for that change.Perkins

Q: What about proper fuel maintenance?

Hatz: Newer diesel engines are much more sensitive to low quality or compromised fuel. Dirty fuel, or fuels past their prime, can cause the engine to run poorly and gum up the injectors and high-pressure pump, as well as the metering unit and pressure control valve. The high-pressure fuel systems are by far the most expensive part of newer engines and can cost an owner more than $10,000 to replace.

Poor quality fuels will also wreak havoc on the aftertreatment systems, possibly poisoning both the DOC and DPF, lowering their life expectancy. Make sure you are following all the fuel guidelines outlined in your engine’s manual.

Cummins: One of the key technology changes for diesel has been the move to super-efficient and clean high-pressure common rail (HPCR) fuel systems. They operate with extremely tight tolerances, meaning fuel quality and fuel filtration are critical areas for rental companies to consider.

Tightening emissions regulations have dictated the use of ultra-low Sulphur diesel (ULSD). This is defined as diesel fuel not exceeding 0.0010 mass percent (10 ppm) sulfur content. Diesel fuel Sulphur levels that exceed the recommendation will shorten the life of aftertreatment components, such as diesel oxidation catalyst (DOC), diesel particulate filter (DPF), and selective catalyst reduction (SCR).

Diesel fuel used needs to be managed correctly to prevent contamination. Contamination can cause premature clogging of diesel fuel filters and premature wear of critical fuel injection system parts. Depending on the size and nature of the particles, this can reduce component life, cause component malfunction, or cause fuel system and engine failure.

Perkins: Along with clear guidance on cleanliness, newer engines equipped with aftertreatment require ultra-low sulfur diesel. In North America and Europe, most fuel suppliers have been offering this for many years. However, it never hurts to check to ensure you're getting the right fuel for your engine. If higher sulfur fuel is used in a newer engine with aftertreatment, it can lead to increased DPF maintenance, more frequent regenerations, or possibly system replacement depending on severity.

Q: What technologies are available to help monitor engine performance and manage service schedules?

Hatz: Hatz Diesel is offering its “Connectivity” services on all electronic engines, which allows the engine to be connected to the Internet of Things (IoT) for remote monitoring and predictive maintenance. This service can adjust the required maintenance intervals based on the engine’s load profile and warn the owner of upcoming maintenance requirements. It allows the owner to see the engine’s operation in real-time, as well as the history of the engine so patterns can be noticed. For example, the owner can see the DPF needs more frequent regenerations when it’s used by one particular operator or at one particular jobsite. Having remote monitoring will also allow local dealers to have visibility on the engine population in their territory, making it easier to stock the proper maintenance kits and spare parts.

Hatz also offers an online engine registration where you can see if your engine serial number has any recalls or maintenance bulletins as well as log the maintenance performed and what parts were used. This allows for a complete engine maintenance history that can be viewed by both the owner and Hatz factory and can help in troubleshooting any issues that may come up.

Lastly, Hatz has an electronic diagnostic tool that can be used on all the electronic engines. This allows the user to view the engine’s parameters in real time, perform several diagnostic tests, and view the entire error code history. This could be vital to rental companies since error codes may be ignored and/or cleared prior to returning the equipment. So, having this error code history is invaluable when finding the correct path for repairs.

Customers with Cummins electronic engines can view prioritized engine faults using the Guidanz mobile app on their cell phones paired with the INLINE mini.Cummins

Customers with Cummins electronic engines can view prioritized engine faults using the Guidanz mobile app on their cell phones paired with the INLINE mini.Cummins

Perkins: Telematics systems that connect the engine or machine to back-office databases are now becoming the norm. These tools greatly improve the ability to track engine performance. Common insights such as fuel consumption, fault code alerts, geolocation, etc., are making it much easier to maintain engines and keep them running at peak performance. Simpler tools are also available such as smartphone apps that allow you to track and document completed maintenance, look up service parts, or connect to individual engines and monitor parameters on sight.

Q: I know there’s been a big push lately for more sustainability. What are some of the latest advancements in fuel types? And what should rental equipment owners be aware of about them?

Hatz: While there have been a number of advancements in biofuels and synthetic diesels, user beware. Make 100% sure that your engine manufacturer has approved the specific fuel type and diesel percentage that you want to use. Not only can a non-approved fuel damage the engine and aftertreatment systems, but most will also change the engine’s emissions levels to the point that they no longer qualify for the required EPA standards. Some engines will allow biofuel, but only up to B20 — some even limit it to B5 or B10. If one of these new fuel technologies is required by the end user, ensure you work with the engine manufacturer to get approval. Sometimes, a different engine dataset and power curve will be required in order to stay EPA compliant.

Also note that even if the fuel is approved by the engine manufacturer, it may have an impact on the maximum power output of the engine. If you are running your engine close to full load on standard diesel, going to a bio or synthetic diesel may cause the engine to behave erratically while the engine is cold or lower the power output and cause the engine to stall during standard operating conditions. Most engine manufacturers will require some real-world testing prior to approving the use of non-standard fuels. Always make sure to check the owner’s manual for approved fuels and any additional requirements for your preferred fuel type.

Cummins: Cummins latest Performance Series engines can operate on B20 biodiesel and HVO100. B20 means a mix of 80% diesel with 20% biofuel that meets the correct fuel specification (ASTM D7467). Operation with B20 biodiesel blends can potentially result in a slight decrease in fuel economy and/or power, depending on the application. Hydro-treated Vegetable Oil (HVO) is a synthetic diesel made from waste products, such as frying fat, animal fats, or wood pulp. It can be mixed with normal diesel oil.

Biodiesel needs even more stringent management than standard diesel to minimize moisture and microbial growth. Due to its poor oxidation stability, it has an expiry date of six months. For this reason, biodiesel is not recommended for low use or seasonal applications.

Q: What’s next for engine technology?

Hatz: Right now, the big push is towards hybrid systems. Hatz has taken advantage of this shift to launch their new Flywheel Integrated Permanent Magnet Generator (FiPMG) systems on their single cylinder electronic engines. These compact systems are much smaller and lighter than your typical engine/alternator combinations making them perfect for mobile applications where size and weight are important.

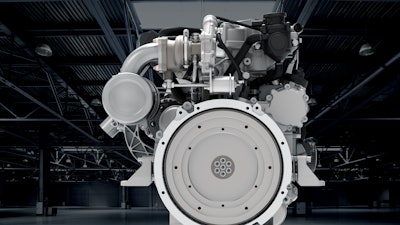

Hatz advises precisely following the maintenance schedule in the engine’s owner’s manual and adjusting the intervals if the engine is operating in harsh or unusual conditions.HATZ

Hatz advises precisely following the maintenance schedule in the engine’s owner’s manual and adjusting the intervals if the engine is operating in harsh or unusual conditions.HATZ

Using a diesel engine as a battery charger is crucial in areas where there is no plug-in power, such as oil fields or new construction sites. The small size of the Hatz FiPMG allows it to be integrated in generators that also harness solar or wind power, without growing the overall generator footprint.

Cummins: Cummins latest Performance Series engines are cleaner, simpler, lighter, more compact, and more powerful than ever. This points to the future direction of advanced diesel, continuing to do more with less, or more capability alongside higher productivity with lower costs and emissions. Smaller engines are already doing the job of what would normally be done by those of larger displacement, with no impact on operations. This will continue.

New technologies such as electric and fuel cells are coming onto the market, but do not meet the business case for operating in heavy duty applications yet. These technologies do not have the flexibility of diesel power to meet the needs of a wide variety of operations, duty cycles, and locations. Diesel will continue being a strong power source for off-highway equipment for some time yet.

Perkins: The next five to 10 years should be very interesting in the engine technology space. Diesel engines still have a lot of life left, and we have continued to see improvement and simplification of aftertreatment systems. We’ll likely continue to see that as well as power density increasing. In other words, smaller engines producing more power. This will help OEMs improve machine design, weight, complexity, fluid usage, and more. Along with these advances in traditional diesel products, new technologies such as hybrids, battery electrification, and alternative fuel power sources will likely be used to complement diesel engines.