XL Fleet has electrified many of the most common commercial and fleet applications with hybrid and plug-in hybrid electric (PHEV) drive solutions for vans, pickups and stripped chassis. “Our customers have driven almost 150 million miles on our systems, saving over 2.5 million gallons of gasoline and reducing their carbon emissions by over 25,000 metric tons,” says Eric Foellmer, director of marketing, XL Fleet.

At the virtual Work Truck Show 2021, the company announces the expansion of a plug-in hybrid electric drive system for select Chevrolet Silverado and GMC Silverado 2500HD/3500 HD pickup trucks and the Chevrolet and GMC 3500 and 4500 chassis cabs. The pickup truck solution will be available in the first quarter of 2021 with availability of the chassis cab solution becoming available in the second quarter. “It is the first PHEV system that is now available for GM fleet products,” says Foellmer.

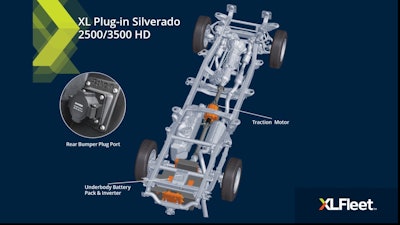

The PHEV systems add an electric motor, an advanced lithium-ion battery pack and control software to the existing vehicle. No other significant modifications to the vehicle are required and no changes are made to the internal combustion engine or transmission.XL Fleet

The PHEV systems add an electric motor, an advanced lithium-ion battery pack and control software to the existing vehicle. No other significant modifications to the vehicle are required and no changes are made to the internal combustion engine or transmission.XL Fleet

The PHEV system has been enhanced over the previous system, with the battery moved to a more convenient location. “The system is mounted all underneath the chassis, which is a brand-new configuration that is in line with our next gen battery pack,” says Foellmer. “The really exciting aspect of this is that everything is under the chassis, you don’t have the limitation of the battery pack being mounted up into the bed of the vehicle, which further adds flexibility for the driver. They can use these pickups as they would any other truck, it’s just an electrified version of it. It’s a really seamless way to get the fuel economy benefits, the sustainability benefits and the reduction in cost benefits that an electrified vehicle gives you.”

The heart of the plug-in hybrid electric drive system is the high-efficiency 15-kWh lithium-ion battery pack which mounts under the chassis.XL Fleet

The heart of the plug-in hybrid electric drive system is the high-efficiency 15-kWh lithium-ion battery pack which mounts under the chassis.XL Fleet

An electric motor is mounted directly onto the driveshaft. “When the driver accelerates, the motor adds an additional 220 ft.-lbs. of torque directly into the driveline,” explains Foellmer. “The result is less wear on the engine, reduced gas consumption and fewer emissions. When the driver decelerates and hits the brakes, the electric motor turns into a generator and stores that energy back into the battery pack so that it can be used again the next time the driver accelerates. The result is a completely seamless experience where the vehicle is regenerating its own power and the driver doesn’t need to worry about the fact that it’s as a hybrid.”

“It provides all of the advantages of an electrified vehicle without any of the limitations,” adds Foellmer. On the HD pickups, the plug-in hybrid system is available on the 6.6-liter engine with the 4x4 driveline. “It’s available on 149-in. wheelbases and up and it’s available on double or crew cab options in any bed size.” On the GM 3500 and 4500 chassis configurations, the system is available on 6.6-liter engines across all wheelbase types.

“Anything that we are putting a plug-in hybrid system on today, we can also put a hybrid system on,” says Foellmer. “Hybrid systems are great for customers who have no access to infrastructure. Their drive cycles don’t allow the additional electrification or any requirements for charging infrastructure. Customers who are in more rural environments or are driving longer distances with their vehicles, these are great setups for hydrid systems. Because we offer both plug-in hybrid and hybrid, you get that full range of electrification, with all-electric trucks also on the horizon.”