By Sarah Bowers, Fraley Construction Marketing, for Klover Prefab

Nearly every builder is experiencing at least a little coronavirus panic these days. Schedules and budgets are up in the air. No one knows how long this will last, who and what will be lost, or what life will look like on the other side. Because construction serves fundamental purposes like creating structures we depend on and jobs we need to survive, it's expected to continue in pandemic conditions. But how? Here’s some advice from one company who is staying ahead of the curve.

The evolution of prefab

The construction industry has seen an explosion of advances since the dawn of the 21st Century. Incorporating machines and robotics, creating stronger, lighter materials, and even simple things like streamlining communication processes have made planning and assembling buildings quicker and easier than ever.

While it’s true that some contractors were slow to adopt prefab in the early days, current innovation has allowed it to keep up with and even surpass the usability of conventional building. Today's prefab reduces waste and worker hours and increases safety and productivity without compromising quality.

The 3D modeling program known as Building Information Modeling (BIM) is used for a controlled and efficient fabrication that flows seamlessly from digital design, to steel stud manufacturing, to final assembly. Prefabricated products include custom load-bearing walls, curtain walls, drywall shapes, and flooring.

Timeless benefits of prefab

Because each construction project is unique, the hurdles that cause project delays tend to vary. Factors such as sequencing of work, worker availability, site conditions, and time constraints can all be alleviated with prefab by accomplishing much of the work off-site. This means the owner can occupy the building faster to start generating revenue.

Having less worker hours on-site also limits liability. In terms of insurance, this is a big win for owner-controlled insurance programs, which obviously subject the owner to most of the liability. It’s also an advantage for contractor-controlled insurance programs because the worker hours don’t get counted against the program. Less worker hours also means less accidents and injuries.

In other words, prefab helps to mitigate a host of concerns. “You don’t have to deal with the weather,” says Curt Johnson, director of business development for Bucks County, Pennsylvania,-based Klover Prefab. “You don’t have to deal with waiting for other trades. It helps control some of those things, as much as construction can be controlled.”

COVID-19’s effect on construction safety

Klover is one of many manufacturing and construction companies adapting to a new world.

“None of us ever thought we would see such a thing (coronavirus pandemic) in our lifetime,” says Tammi Talese, Klover’s director of administrative services. “I still wake up some mornings thinking, ‘Is this even real?’”

Talese appreciates that OSHA is providing updated guidance often. They advise that, for the time being, in-person enforcement inspections will not take place unless there is a fatality or serious incident. Most regular inspections are to be handled completely online. However, OSHA makes it clear that compliance with standards is still an expectation, while acknowledging that with the current pandemic situation some elements may be challenging if not almost impossible, to meet.

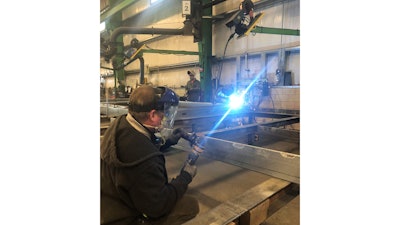

Even before it became a buzzword, the workers in Klover Prefab’s Quakertown panel shop were “socially distanced.” They saw the dangers coming and put protections in place. Still, there are a few work tasks that may require people to come into closer contact than the social distancing rule allows. Klover has doubled up protection by using both a mask and a face shield to ensure that the risk to its team remains isolated. Also, a lot of processes have been given to automation, such as band saw cutting, so workers are able to stay further apart.

Scott Evans, vice president of prefabrication, points out, “Our safety committee has really gone above and beyond the requirements that the CDC lays out. Our original response plan was written and put into place around March 12th. Everyone here has already embraced the necessity of PPE in general, so they were receptive to taking it to the next level.”

More regulations imposed on construction sites can impinge on workflow efficiency. Using prefabricated assemblies makes it possible to spread individuals over a wider area. Social distancing measures mean fewer workers on site, which tends to stretch construction timelines. Building with prefab assemblies can cut on-site time to maintain project schedules with minimal risk of exposure. Pre-assembly allows many issues to be worked out remotely, working from the safety of home rather than gathering in a job trailer.

Keeping in mind these many advantages, Evans says, “choosing prefabrication shows a level of responsibility in this time where limiting exposure is crucial.”

Long-term implications of COVID-19

“Once treatment is found to handle the virus, there will most likely be some sense of being able to go back to normal operations,” Talese predicts. “There will be a heightened sense for everyone about disinfecting, sanitation, and PPE that might not roll back.”

This is a time that calls for creative solutions. There’s a learning curve to things like how to meet hand washing requirements if bathrooms are on the opposite side of the job site, and how to best deal with face coverings when they collect too much dust and dirt. Everyone must put their heads together now and figure out how to maintain the highest level of efficiency while accommodating change.

More than anything else, the necessity to change old habits represents an opportunity. “For users of traditional construction materials and processes, comfortable with the way they've done things in the past and intimidated by change, here is a situation where you must change,” Johnson says. “So, this is the perfect time to eliminate some of those previous barriers of entry, if people were hesitant because of a lack of knowledge and familiarity with the product.”

Builders focused on closing in structures faster to put other trades to working inside should consider integrating prefab. Owners and contractors that give prefab a chance will most likely choose to continue with it once the wide array of benefits are witnessed in action.

The comparison is made to the Green Building Movement of the last two decades: “Everyone got LEED certification, and it really put sustainable practice into construction,” Johnson says. “It changed the way that they approached what they were doing. Prefab is just one of the trends we’re likely to see improve construction industry processes moving forward. This is another instance where doing good is also the right business move. This is an overlap: the concept of safety and the greater good both being served by the same technology.”

With more than 100 years of combined experience in project management, design, engineering, and manufacturing, Klover has a proven track record in large-scale, high-profile projects. These projects range across the healthcare, senior living, commercial, educational, recreational, and military sectors.