Editor's Note: Kim Basham provided this article after a reader inquiry in regards to his article "Reinforcement for Crack Width Control," which ran in the December 2009 issue of Concrete Contractor magazine.

Reader inquiry: "I recently read the article by Kim Basham regarding placement of reinforcing in slabs on grade. I would be interested in an article regarding placement of reinforcing in slabs when in-floor heating tubes are required. Tubes generally are placed on top of the reinforcing and allow for only 1 inch of cover at best. Then there are joint issues and sawing issues. What are the best practices? I have increased slab depth, etc., to accommodate the reinforcing; is there anything else thatcan or should be done?"

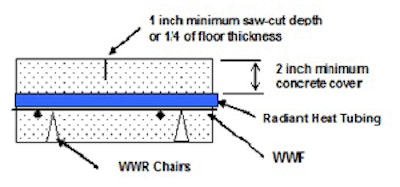

Installing saw-cut contraction joints in radiant-heated floors is similar to standard slab-on-ground floors except placing and maintaining reinforcement and tubing locations are critical. Otherwise, radiant heat tubing can be damaged when saw cutting joints, causing construction delays and expensive repair costs.

As always, space joints at 24 to 30 times the slab thickness or 8 to 12 feet for a 4-inch-thick floor. Protect tubing passing through joints according to the manufacturer's recommendations.

Use welded-wire reinforcement (WWF) sheets, not rolled WWF, to properly support and hold radiant tubing into position. Attach tubing to WWF according to the manufacturer?s recommendations. Typically, manufacturers recommend placing the tubing in the bottom one third or middle of the floor. In any case, protect tubing with a minimum concrete cover of 2 inches. Support WWF sheets on support chairs and consider using 12 x 12 inch wire spacings so workers are not required to walk on the WWF.

Use an early-entry dry-cut or a conventional wet cut saw to install joints. For an early-entry saw, minimum saw-cut depths are 1 inch (maximum is 1.5 inch) and for a wet cut saw the minimum depth is one-fourth of the floor thickness. Of course, joints can be tooled but the minimum depth is one-fourth of the floor thickness. Before placing concrete be sure to check the tubing elevation and carefully monitor concrete or cover thickness to ensure adequate concrete cover over the tubing. When pumping concrete, do not drag the hose across the tubing.

For additional information see "Radiant Heat with Concrete" by Ingrid Mattsson and Gary Fries, Concrete Technology Today, Vol. 18/No. 1, April 1997, Portland Cement Association, available as a free PDF download from the Bookstore at www.cement.org.