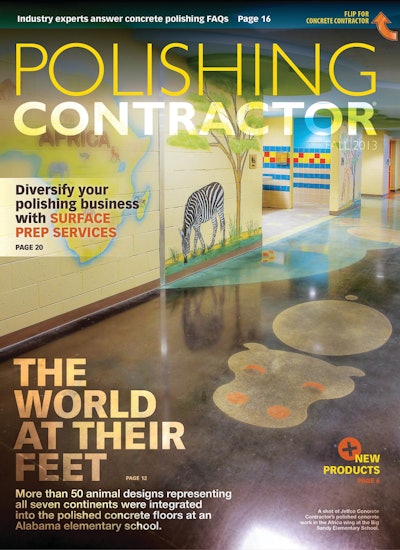

When students enter Big Sandy Elementary School in Tuscaloosa County, Ala., this fall, they will find an inspiring learning environment all around them. Playing off the theme “Discover Earth,” each wing of the new school represents a different continent, and its walls, ceilings and floors are decorated with artwork of the plants and animals that live in that part of the world. As students roam the halls, from Australia to Africa to Antarctica, they will walk over more than 50 animals stenciled onto the polished concrete floors that cover two-thirds of the 75,000 square foot building.

Click here to view a photo slideshow of images from the Big Sandy Elementary School project.

Jeffco Concrete Contractors, Tuscaloosa, Ala., was the polishing contractor that brought this world safari theme to life. President Jeff McCool says over the last five years his company polished floors in nearly three dozen schools across the state. But the floors at Big Sandy were unique. “There was a lot of detail in this project. It took extra time to do these animals, but the crew was experienced and the project turned out really well,” he says.

The case for polished concrete

Ward Scott Architecture, Tuscaloosa, Ala., was the architect of record on the Big Sandy project. James Ward, principal with Ward Scott Architecture, explains the southern part of Tuscaloosa County has experienced population growth over the last 30 years, resulting in overcrowding in its elementary schools. The Tuscaloosa County Board of Education recognized the need to provide more classrooms while members of the communities near Big Sandy Creek welcomed the prospect of having their own school.

“The board’s vision was to provide a school with a warm environment that could be the heart of this community," Ward stated. "The recent school dedication demonstrated the success of the board’s vision when a large ‘Big Sandy’ gathering celebrated the opening of the new school.”

Along with a desire to offer more classrooms in southern Tuscaloosa County and create an anchor for the surrounding community, the board of education wanted an inspiring learning environment that was also budget friendly. That’s where Deborah Roy, Interior Design Professionals, Inc., Tuscaloosa, Ala., came in. As the interior designer on the Big Sandy project, Roy looked for flooring options that would help the school district balance longevity, maintenance ease and budget, all while creating an environment that would spark the imaginations of the young students.

On past projects with intricate design patterns, Roy specified water jet cut VCT. But with polished concrete, she was able to achieve the design she wanted, offer a floor with a long lifespan and cut maintenance costs. “The school system spends up to $15,000 a year on waxing, stripping and mopping its VCT floors. Polished concrete gave us lower maintenance requirements, having only to mop the floors and saving the school system thousands of dollars,” Roy stated.

The polishing process

Jeffco was a sub for the company that won the concrete package on the school project. From the beginning, McCool made it clear to the concrete contractor what he needed from the floor to make the polishing process a success. “I was in his ear to tell him to pour a good, flat floor,” McCool says. “I tell the concrete contractor if I have good concrete to work with, I can give him a good looking polished floor.”

McCool regularly offers the concrete place and finish contractor several tips that will contribute to a concrete surface that it ideal for polishing:

- If it’s going to rain, don’t pour.

- Pay attention to specified F-Numbers.

- Leave a smooth finish — don’t over trowel, and don’t burn the floor.

- Don’t edge your joints.

- Use common sense to avoid stains and damage — don’t let anyone cut anything on the floor with something that could leak oil, and make sure scissor lift tire treads are free of screws and other debris that could gouge the floor.

The Jeffco crew was on the project for eight weeks. Five crew members equipped with three planetary grinders performed the polishing and joint work while two additional crew members performed the template and dye application for the artwork.

The crews worked the floor in phases, starting first by cutting the decorative saw cuts and placing a clear polyurea joint filler in all joints. They used clear joint filler so it would pick up the appropriate color during the dye process.

McCool says the concrete was in good shape for polishing. The grinding/polishing crew started grinding most of the floors with an 80 grit metal abrasive; in a few areas they started with 40s. From the 80 grit metals, Jeffco crew members moved to a hybrid diamond in lieu of a 150 grit metal abrasive.

After the hybrid step, crews applied the first application of densifier. From there they proceeded through typical resin bond abrasives steps, starting at 100, moving to 200, then to 400. The dye process took place after the 400 grit abrasives. It was a little more involved than a typical job because of the artwork and the number of dyes specified throughout the floors. The architect chose 20 different dye shades from three different manufacturers. The construction plans for the project were very detailed, which helped Jeffco’s crews ensure they were using the right dye in the right spot.

For each piece of animal, vegetable or map artwork, the Jeffco crew placed a blank vinyl template where each illustration would be. Then it applied the main surface dyes and densifier. After the detail crew went through and colored in the artwork, the animals and other illustrations got their own shot of densifier. That process was followed up with an 800-grit resin pass, guard and burnish on the entire floor. The two Jeffco crews moved throughout the school in this manner until they completed all sections of the project.

McCool says all parties involved with the project were happy with the results. The school district will enjoy lower maintenance costs and students will gain inspiration with every step.

Project Summary

Polishing Contractor: Jeffco Concrete Contractors, Tuscaloosa, Ala., President Jeff McCool, www.jeffcoconcrete.com

Architect: Ward Scott Architecture

Interior Designer: Interior Design Professionals, Inc.

Construction Manager: WAR Construction, Inc.

Scope of Project: Polish 49,000+ square feet of floors and install 50+ illustrations on those floors throughout a school.

Key Products and Equipment: HTC 800 grinder; SASE PDG 8000 grinder; SASE tooling; Prosoco densifier and guard; dyes from Scofield, Prosoco and Ameripolish; Hi-Tech Systems polyurea.