Changes in building code requirements have prompted the arrival of a new generation of post-installed anchors for use in both cracked and uncracked concrete. Because of these changes, post-installed anchors must now undergo a more demanding series of tests. These tests determine how reliable the anchor is when it's installed under adverse conditions and how sensitive the anchor is when exposed to severe conditions during its service life. The most severe condition is when concrete cracks during the life of the anchor. Unlike previous anchors, such as old-style wedge anchors and drop-ins, the new generation of anchors is designed to perform even if concrete cracks. Since these new concrete anchors look similar to the old generation, it's important that concrete contractors understand the new rules and install anchors that satisfy the new building code requirements and meet the approval of their design engineers.

Anchors must meet the new codes

The code changes require designers and contractors to make different choices. The 2006 International Building Code (IBC) now references a new design method for post-installed mechanical anchors. This design method, ACI 318 Appendix D, basically establishes the design rules for anchoring to concrete. In the past, post-installed anchors were "alternatives" to the code and building officials approved them accordingly. Now, post-installed mechanical anchors are included in the code and are required to be designed in accordance with Appendix D of ACI 318. Post-installed mechanical anchors used in concrete are subjected to new pre-qualification tests (ACI 355.2). Adhesive anchors also are governed by testing and assessment requirements (ICC-ES AC308). It's important to note that most post-installed anchors used previously in the field are not suitable for use in "cracked" concrete.

What causes concrete to crack?

Cracking in concrete occurs for various reasons and under diverse conditions. Concrete may crack during a seismic or high wind event or due to a dynamic live load condition, such as cars in a parking structure. It may even crack during the curing process due to shrinkage. Cracking is generally caused by tension in the concrete.

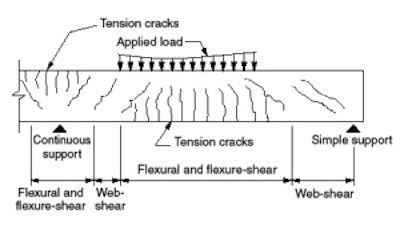

Figure 1 shows a reinforced concrete beam on supports. As the concrete member is loaded, you can see the locations of potential tension cracks. Concrete requires embedded reinforcing steel to transfer tension across cracked sections of the member. These cracks, most too small to be readily visible, impact the load-carrying capacity of post-installed anchors. Therefore, anchors must now be pre-qualified for use in "cracked" concrete and designed in accordance with accepted design requirements. These requirements also mandate that post-installed anchors perform even if a crack were to propagate through the axis of the anchor during the life of the anchor (see Figure 2). If design engineers determine that conditions do not exist that will produce a crack in the concrete, they still must choose an anchor that has been pre-qualified for "uncracked" concrete per the new test requirements.

Cracked concrete solutions

As we know, anchor performance can be critical in the field, so you want to make sure you use anchors that have been pre-qualified and are recognized under the current building code for cracked and/or uncracked concrete conditions. Most of the anchors that have been used for years on jobsites are not qualified under the current building code for concrete installations. Drop-in anchors and wedge-type anchors, for example, are now "unqualified" for cracked concrete. In addition, most adhesive anchors are not acceptable for use in cracked concrete.

To address the changing landscape of requirements, manufacturers have developed products that meet the new requirements. Some products have been redesigned to satisfy the new criteria. In Figure 3, the anchor on the left is not qualified. The anchor on the right, which has been redesigned, is qualified. As you can see, the new wedge-type anchors acceptable for use in cracked concrete look very similar to the old-style wedge anchors, making it more important for installers to verify they are using qualified products. The new anchors, which are designed using different expansion mechanisms and materials, install just like their older counterparts but now will perform even if concrete cracks during the life of the anchor.

Similarly, adhesive anchors that have been pre-qualified for use in cracked concrete look like those products no longer acceptable. One distinguishing characteristic is that the procedure for hole cleaning is now much more detailed for installers to follow. Large diameter screw anchors that have been pre-qualified also look identical to those that have not been qualified. For engineered design projects, designers must now specify approved products. If there is any doubt on which product you should install, consult with your engineer.

To differentiate between an anchor that is pre-qualified for use in concrete and one that is not, contractors must be discreet in their purchasing decisions. It's important to review construction documents, engineered designs and the manufacturer's literature and packaging to verify which anchor is appropriate for use. However, since the number and types of post-installed anchors that have been tested and approved for use in cracked concrete is quite small and familiar products are now "unqualified" for use in cracked concrete, contractors must coordinate with their engineers and be careful when making product substitutions on the job.

The new qualification prerequisites and design requirements clearly distinguish the next generation of post-installed anchors from the previous models. The key is knowing what to look for to ensure you're using the right pre-qualified anchors. Although the number and types of post-installed anchors that have been tested and approved for use in cracked concrete is quite small, it continues to grow as manufacturers bring new products to market. As more products become available and engineers and contractors become familiar with the rules and requirements, using the new generation of anchors will become second nature in the field.

Jeffrey J. Dunagan, P.E., is the manager of engineering for Simpson Strong-Tie Anchor Systems. He can be reached at [email protected]. Chris LaVine is a senior engineer for Simpson Strong-Tie Anchor Systems. He can be reached at [email protected].