MIT published news – reportedly solving a riddle that’s questioned the construction culture for decades. Researchers from MIT, Harvard University, and laboratories in Italy and Switzerland have published their latest findings in the riddle behind the lifespan of Roman concrete.

The latest issue of Science Advances includes a paper by MIT professor of civil and environmental engineering Admire Masic; Linda Seymour, PhD; Janille Maragh, MIT; Paolo Sabatini, DMAT (Italy); Micel Di Tommaso, Instituto Meccanica dei Materiali in Switzerland; and James Weaver at the Wyss Institute for Biologically Inspired Engineering at Harvard University.

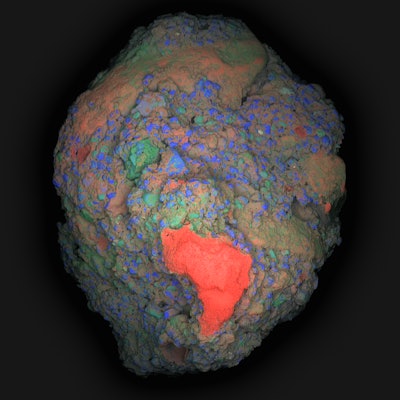

A calcium-rich lime clast (in red), which is responsible for the unique self-healing properties in this ancient material, is clearly visible in the lower region of the large-area elemental map (Calcium: red, Silicon: blue, Aluminum: green) of a 2 cm fragment of ancient Roman concrete.Courtesy of the researchers | MIT

A calcium-rich lime clast (in red), which is responsible for the unique self-healing properties in this ancient material, is clearly visible in the lower region of the large-area elemental map (Calcium: red, Silicon: blue, Aluminum: green) of a 2 cm fragment of ancient Roman concrete.Courtesy of the researchers | MIT

According to the latest research, the secret required a closer look.

Where they were once thought to be more of a mistake in the concrete mix, Masic wasn’t entirely convinced.

New insight via high-resolution multiscale imaging and chemical mapping techniques pointed against what was originally believed. Instead, the new hypothesis was whether or not the Romans utilized the more reactive quicklime. If so, the key to the durability of Roman concrete was hot mixing. This, according to Masic, would have reduced the curing and setting time and ultimately allowed a much faster construction.

Understandably, researchers are excited. (Aren’t we all? Really?) The team is working to commercialize the modified cement material, with Masic mentioning that “it could improve the durability of 3D-printed concrete.”

With the globe’s effort in reducing the carbon emissions and reaching Net-Zero concrete construction, cracking the code behind the durable Roman concrete might allow new mixes to be durable light-weight concrete.