The $1.2 trillion infrastructure plan that President Biden signed into law in November will present general contractors with a bonanza of business opportunities. The bill allocates $110 billion to the repair of highways, bridges, and roads. It includes $66 billion to be spent on the repair of Amtrak’s Northeast Corridor rail system. It budgets for $25 billion to be invested in upgrading our airports and $55 billion on water and wastewater infrastructure. The president has compared this surge in infrastructure spending to the building of the transcontinental railroad and the national highway system, and contractors are licking their lips in anticipation as they contemplate how their businesses will benefit.

But while contractors are gleeful about the passage of the bill, taxpayers should be concerned. After all, we’re footing the bill for this infrastructure extravaganza. And the companies that we’re entrusting to modernize our ports and upgrade our aging bridges are not always known for their efficiency. According to McKinsey & Company, large construction projects are typically completed up to 80% over budget and take 20% longer to deliver than originally scheduled. Is America going to settle for such lackluster performance on these essential infrastructure projects? As the ones funding this work, we taxpayers deserve better.

So how can the general contractors on which we depend boost their performance? As both a tech entrepreneur and an experienced builder, I believe that the best opportunity for improvement is for general contractors to double down on technology. The construction industry has characteristically been slow to embrace new technologies. It is a sector, after all, in which Microsoft Excel has long served as the answer to all manner of problems above its pay grade. However, in the last several years, we’ve started to see a rising interest in tech-driven innovation in construction, a change that is best illustrated by the growth in venture capital investment in the “contech” segment. According to the market intelligence firm CB Insights, contech startups received $5.1 billion in funding from 2015 to 2019. But this year alone, such companies will receive $1.3 billion, which represents 56% growth and a new funding record.

These investments are funding a wide variety of companies that will be able to help general contractors to truly “build back better.” In robotics, for example, we’re seeing the emergence of robots that are tackling all manner of tasks — tasks they are accomplishing faster and cheaper than humans. Case in point: Volvo now makes an autonomous vehicle that moves material and tools around large job sites. Hilti’s Jaibot marks and drills overhead anchor holes, a repetitive task now performed efficiently by the robot. And the SAM100, developed by Construction Robotics, operates alongside a bricklayer to eliminate manual tasks from his work, enabling him to lay up to 3,000 bricks a day, a six fold increase in speed.

Also promising is the emergence of exoskeletons — wearable technologies that give construction workers new capabilities and also reduce injuries. For example, the Ekso Works Industrial Exoskeleton enables construction field team members to lift and use heavy power tools as if they weighed nothing at all. The Franco Exoskeleton by Mawashi makes it easy for masons to lift and place heavy masonry blocks. And Noonee’s Chairless Chair reduces pressure on the knee and the rest of the leg for workers who stand for long periods.

At ALICE Technologies, we’re bringing artificial intelligence (AI) to the world of complex, large-scale construction. While AI sounds futuristic, it’s already used across numerous industries. For example, in the customer service arena, Yalo is providing companies with AI-powered chatbots that enable their customers to do everything from change flight times to place orders for groceries. In healthcare, Moderna, one of the pioneers of the COVID-19 vaccine, is using AI in drug discovery.

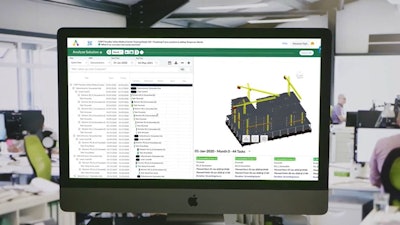

ALICE began with a focus on preconstruction planning, a field in which schedulers had long relied on tools like Excel, Microsoft Project, and P6, a tool originally developed decades ago. With the introduction of the ALICE platform, contractors could use AI to generate thousands of fully-loaded construction schedules in an afternoon — and then experiment with “what if” analysis to see how changes might affect their plans (e.g. “if we added a second tunnel boring machine, could we complete this airport tunnel project faster, and would the decrease in build time be worth the cost of the second machine?”) Since our early days, we’ve expanded into the construction phase and now give contractors the AI tools to keep their projects on schedule, or to revise their schedule and get a project back on track if it falls behind.

By adopting innovative technologies like these, general contractors will be able to reduce their risk and improve their ability to deliver projects on time and on budget. We’re convinced that they can do so successfully. And in making these changes, general contractors will be able to help the American public to squeeze the greatest possible value out of this substantial investment that taxpayers are making in enhancing our country’s infrastructure. With $1.2 trillion on the line, the time to embrace such technologies is now.