LAS VEGAS -- Tekla Structures, the most advanced building information modeling (BIM) software on the market, includes an accurate, dynamic and data-rich 3D environment, the benefits of which are evident for the above projects and in all the building information models that were submitted for the 2011 Tekla North America BIM Awards.

Each year Tekla hosts a North America BIM Award competition open to all Tekla users who have modeled projects with the software during the preceding year. The BIM Awards competition is held in conjunction with Tekla's Annual North America User Meeting, which this year took place in Las Vegas, Nevada, August 11-13.

The growing popularity of Tekla Structures and the adoption of 3D modeling attracted a record number of Tekla Structures users to submit their 3D models. Models were submitted for judging in three categories:

- Category 1 – BIM

- Category 2 – Steel

- Category 3 – Concrete

Participants submitted web models, descriptions of their projects, photos, and other supporting material. Online voting opened to the public prior to the 2011 Tekla North American User Meeting. The top projects then went to a panel of three judges: Rafael Saks, Associate Professor, Technion - Israel Institute of Technology; Heather Brown, Director & Associate Professor, Concrete Industry Management at Middle Tennessee State University; and Chris Moor, Director Industry Initiatives, American Institute of Steel Construction (AISC).

The winners for each category were announced at a special award dinner Friday evening. Congratulations to the following winners!

View these winners and all submissions at: http://www.tekla.com/us/Documents/BIM-awards-2011/categories.html

Category 1 Winner -- BIM -- DPR Construction and IPD Team

Sutter Alta Bates Patient Care Pavilion

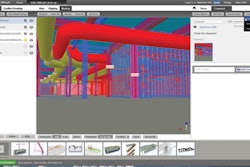

Patient care pavilion addition -- The addition to the Alta Bates Summit Medical Campus (ABSMC) is a $298 million, 13 story patient care pavilion and future home of over 200 licensed beds beginning January 2014. The highly collaborative Integrated Project Delivery (IPD) team was faced with many challenges. From planning logistics for a congested urban site to constructability analysis of a congested rebar design, the use of BIM in the ABSMC project has become more than just a benefit; it has become a necessity.

Project team determined to make up delays with BIM -- The ABMSC project began drilling piles in January 2011 with a 31 day schedule delay due to permitting, weather, and unforeseen site conditions during demolition. Through hard work, collaboration, and the ability to quickly react to field conditions using BIM, the current schedule is now just eleven days delayed. The project team plans to make up all 31 days of delay before the start of steel in October, 2011.

Category 2 Winner – Concrete -- CCM (Contratistas Civiles y Mecánicos, S. A.)

Galeria 360

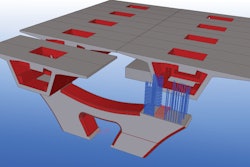

Commercial mall project -- The Galeria 360 project is a 1,045,175 sq. ft. commercial mall currently under construction in Santo Domingo, Dominican Republic. This project has two levels of underground parking and two levels for commercial purposes. The foundations are made with reinforced concrete with a depth of 39'.

BIM enhances project collaboration -- This project involves all of the disciplines for what BIM, especially Tekla was conceived; disciplines like steel structure, cast in place concrete, precast concrete and tilt-up. Besides having all these disciplines on the project, all of them interact and use connections and assemblies of tilt-up with the steel structure, tilt-up with cast-in-place concrete and prefabricated concrete with steel, where most of the connections were developed by our detailer team.

Category 3 Winner – Steel -- InteliBuild, a division of Canam Group

New Marlins Ballpark - Retractable roof

Widest stadium retractable roof -- Composed of over 7,000 tons of high-strength steel, the span of each retractable roof panel from rail to rail is approximately 530 feet at each lower panel and 566 feet at the upper panel. The opening created by the long span of the 45 foot deep upper panel truss is wider than any NFL retractable roof stadium. The south track beam structure is lower than the north track beam to minimize the overall building height and allow for roof panel movement due to the affects of sun and wind.

Advance coordination results in smooth field testing -- Because of advance coordination through simulations of the sliding roofs, the first testing in the field went smoothly without any interference between the 3 roof panels. The most complicated element of the project was the wishbone plate assemblies located on the north end of each of the 12 trusses. They were composed of over 50 plates and weighed around 16 tons each.