In the world of construction equipment,  ThermoLite Solar Panels are ideally suited for construction applications.Thermo King

ThermoLite Solar Panels are ideally suited for construction applications.Thermo King

When a battery sits in a low charge state for long periods of time, it loses its ability to be recharged and hold the power to start equipment again. In recent years, this has become more common as heavy equipment now comes loaded with more electronics, sensors and other small parasitic loads that drain batteries down faster than ever. For many fleets, jump starting or replacing batteries has become a costly part of everyday business.

So what can you do to address this problem? Thankfully, there is a recent innovation that can help prevent these issues and save you significant money over the long run: solar power for construction vehicles, with panels designed for the harsh environment of construction applications.

Solar power is an ideal solution for the construction world, as a small amount of daily charging can offset parasitic loads and keep batteries in peak condition. This means batteries can last up to 10 years without replacement and that jump starts can be eliminated.

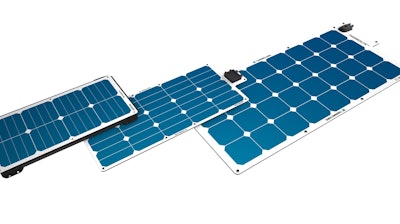

Until recently, solar technology had not advanced enough to enable enough power to be placed on the roof of equipment or to allow the panels to survive the daily grind on-site. Recent advances in solar innovation (called back-connect solar technology) now allow solar panels to be flexible, thin, and resistant to scrapes and the damage from debris.

In addition to extreme durability, the panels are now so sensitive to light that regular cleaning is no longer required, as the panels will still produce power even when covered in dirt or during cloudy weather. Also, in northern territories where snowfall occurs, a frequent concern is how that will affect solar production. Since solar panels are designed to absorb light and heat, snow will rapidly melt off of the panels and a smooth hydrophobic surface means that the snow will typically slide off quickly. Even in freezing temperatures, panels will melt off snow and be back to peak performance within a day or two after snowfall. This new technology also allows for a significant amount of power to be placed in a small space, like the cab roof of your equipment. All of these breakthroughs have given us a solar panel that is compact, flexible, durable, and easily installed on almost any piece of equipment.

So how much can this new technology save you? The typical Return on Investment (ROI) for adding solar to a vehicle is typically less than a year, and is made even more attractive by a 30% federal tax credit. The return on investment is calculated around three categories: battery replacements, operational efficiencies and fuel savings. Combined savings in these categories can add up very quickly for both small and large size fleets, so let’s expand on them.

Battery replacements are a frequent problem and present the largest opportunity for savings when solar is introduced into the equation. Early battery failures occur when batteries are allowed to sit in a deeply discharged state for a long period of time, such as when equipment sits for extended periods at an idle jobsite and small power draws from electronics slowly drain the battery down. Even the newest, best battery technologies (such as Absorbed Glass Mat [AGM]) cannot sit for long periods in a depleted state and need to be replaced. The easy way to keep these small loads from draining the battery is to offset them with daily solar charging. Solar panels can keep batteries in peak condition and allow them to last 8 years or longer without needing replacement.

Operational efficiencies are realized when your business has less downtime due to battery failures. Arriving at a jobsite and having to jump start or replace a battery costs you valuable operational time. This is especially true during short daylight hours or on high-pressure jobs where every hour counts and your equipment needs to be able to start up without delay.

Fuel savings is the icing on the cake as far as ROI with solar. Fuel savings result from solar power constantly putting power back into the battery. This means that the alternator, which is typically required to supply 100% of power, can take a little break, resulting in an offloaded engine that burns less fuel every day.

Combining these savings opportunities gives a rapid payback that is recognized almost immediately. To further speed the payback, a 30% federal tax credit is applicable for all parts and labor associated with solar installations.

It’s also important to remember that you don’t need a huge solar installation or investment to see gains. The amount of solar required to achieve the rapid payback is typically less than 50 Watts, which can now fit into a 1 x 2 foot space and can directly charge the equipment’s 12V or 24V battery system. Furthermore, since solar panels are a current source and not a voltage source, they won’t artificially raise the equipment’s battery voltage. This means that solar and alternator charging can most often occur simultaneously which further helps to offload the alternator.

Installation of flexible solar is easy with plug and play connectors and electronics with visual feedback that help prevent bad installations. Panels are peel and stick, so no holes need to be drilled and the cables run directly to the battery system.

So next time you jump start a piece of equipment or replace a battery, look up at the sun and remember that it could be the answer to your problems.

Ed. Note: Paul Kroes is the Power Solutions Business Development Manager at Thermo King