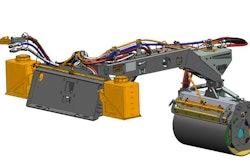

Road Widener offers the patented FH-R material placement attachment to support the safety and process of utility trench backfilling operations. The FH-R is a solution for material placement, dispensing topsoil, gravel, asphalt, limestone and more — all with an attachment compatible with machines found on construction sites.

The remote-controlled design of the attachment allows the operator of the host machine to control the attachment via remote control, supporting safety by reducing the danger of additional workers standing along the jobsite.

“The FH-R cuts out jobsite clutter and enhances efficiency by eliminating extra machines and reducing the multi-step process down to just two passes, dispensing and compacting,” said Lynn Marsh, Road Widener president. “Utility contractors will get a high-quality, profitable and efficient solution for their business that makes for an unrivaled total cost of ownership.”

The remote-controlled attachment connects to most skid steers, compact track loaders, road graders and wheel loaders, operating off the host machine’s engine and hydraulics. The attachment supports a variety of tasks including backfilling, road widening, road shoulder repairs, remediation and aggregate placement. The material is poured into the hopper at the top of the FH-R and then dispensed via remote control in adjustable lay down widths from 1- to 6 ft. (.3 to 1.8 meters). The attachment dispenses up to 20 tons of material in under 10 minutes.

“Our customers often tell us the swift capabilities of the FH-R have a tremendous effect on their business,” Marsh said. “With labor shortages spiking, contractors are often running with a lean crew. However, the demand for infrastructure remediation is only rising. The FH-R helps to solve this challenge by efficiently and precisely laying material with only one operator. Some of our customers can lay up to five linear miles a day with our machine, making it truly a gamechanger for any business, no matter the size.”

The FH-R works with standard and high flow hydraulics and has five grease fittings to maintain. The attachment is available in left, right or dual dispensing configurations. Without an engine, powertrain or any associated parts of its own to service, the FH-R requires minimal maintenance. The attachment is available with an optional universal mounting plate to ensure compatibility and connection.

The compact design of the FH-R fits on the same commercial trailer as the host machine and can be towed by a common pickup truck. Additionally, the FH-R’s small footprint decreases traffic disturbance and danger on busy highways and narrow backroads. With a 360-degree swivel caster, the FH-R can maneuver around posts, guard rails or any common objects.

*Updated on August 16, 2023