Earlier this week, Caterpillar announced the latest additions to its Next Generation lineup with the introduction of the 302.7 CR, 303 CR and 303.5 CR compact radius hydraulic mini-excavators, which incorporate “industry-first features” for the 2.7- to 3.5-tonne class. These brand new models replace the 20-year-old 302.7 D, 15-year-old 303 E and 10-year-old 303.5 E2 designs.

The Next Generation platform is designed to deliver a consistent operator experience throughout the 1.5- to 10-tonne, with standard features such as stick steer, cruise control, operator adjustable settings, tilt-up canopy or cab and Bluetooth radio connection.

“Every Next Gen model has those same features and benefits,” says Greg Worley, Caterpillar market professional. “The commonality for our customers and operators [means] they’re not reinventing the wheel every time they move from machine to machine.”

The layout of the cab is similar across models for ease of operation. “A lot of operators will hop multiple models throughout the week – they might be in a 303.5 today and a 310 tomorrow,” Worley comments. “Now, we’ve made that a common experience across the entire range. If I can operate a 336, I'm pretty sure I can operate this because it looks exactly the same.”

More Capabilities in a Compact Package

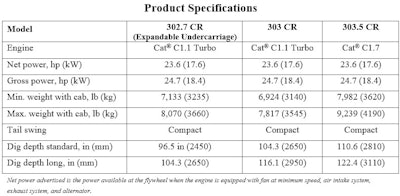

The new Next Gen mini-excavators offer standard- and long-stick configurations, with standard digging depths ranging from 96.5 to 110.6 in., and long stick digging depths extending from 104.3 to 122.4 in. Interchangeable counterweight packages enable machine weight to be tailored to job requirements. The “light” counterweight option adds 221 lbs. to the machine weight, while the “extra” adds 551 lbs.

The 302.7 CR, 303 CR and 303.5 CR come with fixed undercarriage widths of 59.1, 61.0 and 70.1 in., respectively. The 302.7 also offers an expandable alternative.

“A big determining factor for these [smaller] machines is access – trying to access someone's backyard, trying to get on the side of a street through an alley,” says Mark Perkes, Caterpillar product application specialist. “One thing we have on this 302.7 that we've never had on this size machine before is an expandable undercarriage.”

The expandable undercarriage allows the track to be hydraulically retracted to a width of 53.3 in. to fit through gates and other confined access areas and expand to 70.1 in. for enhanced digging and lifting stability.

Power and Performance

Design enhancements to the 302.7 CR, 303 CR and 303.5 CR enable up to 10% more performance in travel and trenching compared to the predecessor models. Hydraulic system upgrades improve lifting performance and cycle times, while customizable operator settings improve efficiency.

Load-sensing hydraulics with a variable-displacement pump provides up to 26-gpm oil flow. High main-relief pressures coupled with flow rate, generate the hydraulic capacity for high digging and lifting forces and more efficient use of a range of attachments. The standard auxiliary system, complete with quick-disconnect lines, provides a choice of one-way, two-way or continuous flow.

Two travel ranges with speeds up to 2.8 mph help to facilitate moving around the jobsite. Standard cruise control minimizes operator interaction when traveling longer distances between work locations.

Improved Operator Experience

The new models come with enhanced machine security options, with both a passcode and a Bluetooth key start available. The advanced touchscreen option provides intuitive machine function control and easy monitoring of critical operating parameters, including fuel level, coolant temperature and maintenance records.

The 302.7 CR, 303 CR and 303.5 CR come with a choice of canopy or a sealed and pressurized cab enclosure, which can be equipped with heating and/or air conditioning and includes a front window that slides upward to conveniently store overhead.

Commonality Aids Serviceability

Expanded use of common parts throughout the Next Generation excavator line, along with damage-resistant exterior construction, help to reduce parts inventory investment and lower repair costs. The tilt-up cab design also offers easy access to key components for servicing.

“One thing that customers have told us is that daily maintenance, it’s a necessary evil, but if we make it as easy as possible, it's much more likely to get done,” says Perkes. “We have continued that tradition of making it extremely easy to do your daily maintenance on these new machines. All of your daily maintenance checks can be done by accessing the side panels that can be independently opened and closed in any order, and you can get ground level access.”

Increased service intervals mean the excavators spend more time on the job and less time in the workshop, as well.

Combined, these features lower total ownership costs up to 5% compared to previous models.

Information provided by Caterpillar and edited and enhanced by Becky Schultz.