Construction technology company Topcon, which specializes in imaging and digital tools, has announced expanded capabilities for its machine control functionality. This is one of many announcements from Topcon in recent years about improved technology and compatibility within its machine control, GPS and robotic total station platforms.

Topcon's 3D Excavator System, which includes GPS technology, is now more compatible with Caterpillar's 2D excavator systems. Topcon's system works with Caterpillar factory-installed NGH sensors and Cat Assist features.

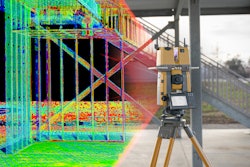

Topcon's system is designed to provide real-time, dynamic, on-screen bucket location and design views, to cut grade faster and more accurately. The operator can create, cut and check designs from the cab. The automation features are also designed to reduce operator fatigue.

According to Topcon, the new functionality will simplify installation of Topcon's system within the Caterpillar 2D excavator systems, with the help of Topcon and Caterpillar dealers.

“With increased pressure for productivity and accuracy, and the industry’s need for skilled operators, the solution is timely," said Jamie Williamson, Topcon executive vice president. "The customer will have the benefit of Topcon 3D Excavator System and Caterpillar Assist features working together. Once the user is acquainted with the combined system, it will be easy to be a more productive operator.”

Topcon

Topcon

![Hcm Ax Landcros Dual Branded Logo[25]](https://img.forconstructionpros.com/mindful/acbm/workspaces/default/uploads/2025/11/hcmaxlandcros-dual-branded-logo25.Qhg3vUCjoK.jpg?ar=16%3A9&auto=format%2Ccompress&bg=fff&fill-color=fff&fit=fill&h=135&q=70&w=240)