This article and its sidebar were adapted and edited from the original versions, "Tire Maintenance and Avoiding Tire Blow-Out," "3 Signs Your Trailer Needs Repair," and "5 Common Trailer Tire Questions" on the Felling Trailer website with permission from the company. The piece was written by the team at Felling Trailers and edited by Alexis Sheprak for Rental.

Owning a trailer comes with plenty of benefits, whether you use it for work to haul your equipment to and from jobsites or for renting out to your customers. While trailers are great when you need them, they also require regular maintenance and occasional repairs. Without the proper maintenance, you may end up dealing with a costly trailer repair.

Know When to get Your Trailer Serviced

A trailer in need of repair can be dangerous for you and those on the road with you. It’s a good idea to know the signs that your trailer needs repair before it’s too late. Let’s take a look at some of the indicators for when your trailer needs to be repaired and some of the most common repairs you could end up dealing with.

Hard to Stop

When it becomes difficult to stop your trailer, it’s time to check your braking system and axles for repair needs. If you suspect the brakes aren’t working or would just like to check them for some preventative maintenance, it’s a relatively easy task. First, lift the trailer up on jack stands. Then, whether they're electric or hydraulic brakes, pull the breakaway and try to spin the wheels. The wheels should be locked up. If the wheels can turn, then further diagnosis would be necessary.

If the trailer is air brake equipped, it’s common to hear an audible air leak within a braking system, but any issues you notice stopping the trailer need to be taken seriously. If you are still struggling to get your trailer to stop, it could also be a sign of a bent axle or another needed repair. Depending on how the trailer is acting, you may need to take off one of the tires to further investigate and discover the issue.

Faulty Lighting

Just about every trailer comes equipped with lights and wiring, and sometimes it needs to be repaired. If the lights are flickering or not working, this can be a significant safety issue. You may be dealing with something as simple as a blown fuse, a loose connection, or, something as severe as faulty wiring or electrical shorts.

Tire Failure

Tire maintenance is undoubtedly the most critical safety component on a vehicle. Where the rubber meets the road affects traction, handling, steering, stability, and braking. Because of this, a sudden tire failure can have serious consequences, especially if it occurs at highway speeds.

Many tires today are capable of going thousands of miles or more — provided they are properly installed, maintained, and inspected regularly. With proper care, tire maintenance, and “normal” use, most tires will go the distance without a problem. But sometimes tires fail.

When the trailer starts to pull your vehicle to one side or another, you might have a tire issue. Before each tow, you should check your trailer’s tire pressure and inspect it for wear. During the inspection, you might notice a crack or bulge in one of the tires. If this is the case, it’s time to get your trailer tires checked out and changed before you end up stranded on the side of the road.

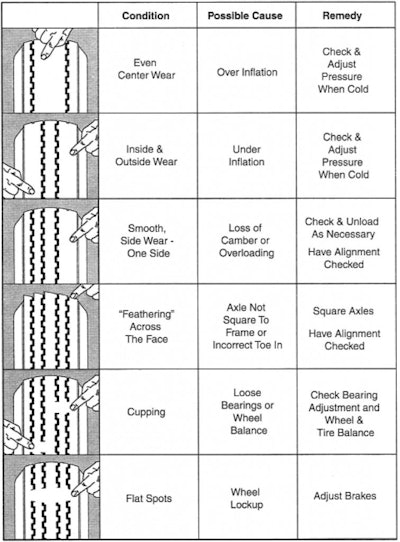

Shown are common types of trailer tire wear and how to address them.Felling Trailers

Shown are common types of trailer tire wear and how to address them.Felling Trailers

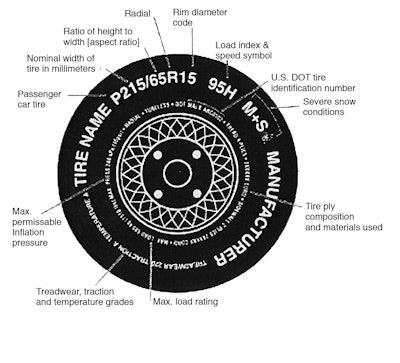

But to do that requires proper maintenance. For starters, it is recommended to carry a tire pressure gauge in your tow vehicle. Secondly, pay attention to these key terms:

Underinflation: Check your tire’s sidewall for recommended PSI (Max Permissible Inflation Pressure). If tire pressure is lower than recommended PSI, take note of the difference between measured pressure and correct pressure, then add the missing pounds of air pressure to each tire that is underinflated.

Overloaded: Check tire placard, know your capacities, and on the tire face is listed the Load Range as C, D, E, G, etc. The Load Range tells you what the weight capacity of your tire(s) is. Surpassing this specified load limit can result in tire failure.

Potholes and other Road Hazards: Hazards on the road can impact the internal structure of the tire and be the cause of a blowout in months to follow.

Weather Checking: If a trailer sits stationary and is exposed to the environment for extended periods of time like weeks, months, etc., the tire’s surface can start to crack. This typically occurs on the sidewalls or at the base of the tread grooves causing weather checking or ozone cracking. If this is observed, then it's time to start looking into replacing the tires.

Lack of Maintenance: i.e. all of the above

The most common trailer repair you will encounter will have to do with your tires, but beyond that, there are other common wear parts that will need to be repaired or replaced, such as:

- Hub replacement

- Bent axles

- Repacking bearing

- Wiring/lighting repair

Anytime your trailer isn’t towing normal, you want to diagnose the problem. Sometimes, it’s as simple as inspecting the trailer and finding the issue. But you should always complete a pre-trip walk around before each use.