The safe planning of mast-climbing work platform (MCWP), lift, or hoist operations should start long before the machine is delivered on site.

First, the identification of the tasks to be undertaken, together with the location and timing, is essential in specifying the appropriate piece of equipment required to do the job. Next, it is necessary to plan all the details for the delivery, assembly, operation, dismantling, and return processes. Added to these is the identification of control measures to address potential hazards, and implementing monitoring and supervision to ensure the safe use plan is followed.

It is crucial, as with all other modes of powered access equipment, that those involved in the installation and use of equipment MUST be trained. Remember: IPAF can offer highly professional, accredited training on MCWPs, hoists, and lifts. The training required for the roles involved in the planning and installation of a MCWP or a hoist are as follows:

Installers are responsible for the safe and appropriate installation in all standard configurations indicated by the manufacturer. They should be able to perform installation, conduct a final appraisal of the installation, and hand over the completed MCWP to the user with any guidance on its proper use.

Advanced installers are responsible for the installation in all configurations including special configurations and on tailor-made projects. They must be able to perform installation, conduct a final appraisal, hand over procedures, and conduct a thorough inspection.

Once the machine has been installed and thoroughly checked, it can be used. Then the following levels of training apply:

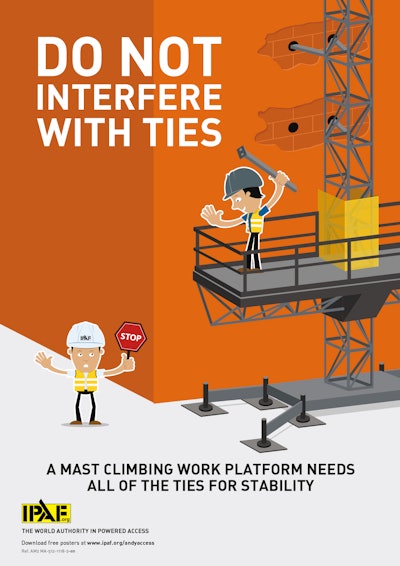

Operators are persons who have been trained to operate the machine, with full knowledge of the controls of the equipment. They are able to carry out pre-use/daily inspections and perform the emergency descent. While the MCWP operator must be the one authorized to move the work platform, it is also recommended that all persons working from the platform receive this training. The safe operation of a MCWP can be impacted by those working on the platform, such as proper loading of the platform, movement of guard rails and mast ties, and exiting at height, so all personnel must have a basic level of knowledge to work safely on the MCWP.

Demonstrators are persons with full knowledge of the operation of the equipment. They are able to perform the emergency descent, carry out pre-use/daily and weekly inspections, and ensure that these take place. In addition, demonstrators are in charge of performing familiarization to users and trained operators.

IPAF’s MCWP, lift, and hoist training programs that are available in the U.S. are modular, and according to the level that the trainee wants to achieve (operator, demonstrator, installer, advanced installer, or trainer), the instructor delivering the training will go through the correspondent modules. After each module completion, the Instructor runs a written or practical test. All courses have a practical assessment where trainees are asked to perform specific tasks to prove their practical knowledge and skills acquired during the course.

When properly managed and used, MCWPs, lifts, and hoists are extremely safe systems. They are increasing in popularity on sites across the U.S., and in the post-COVID-19 era, MCWPs in particular are proving very useful for work crews to carry out construction or maintenance tasks while observing social distancing.

However, there are some hazards involved in the installation and use of this equipment. The major causes of injuries and fatalities can usually be traced back to a lack of training, improper use, and inadequate inspection. During erection and dismantling processes, typical hazards include manual handling of heavy items, failing to bolt up the mast sections correctly or securing ties incorrectly, leading to the drive unit falling over, material projections during the drilling of mast tie anchorages, trapping of persons in the drive mechanism, especially if they are on the platform when the last ties are released during dismantling, and insufficient stability provided by the base frame or chassis alone.

Owners, rental companies, and installers of this equipment report that they are frequently called to sites to assist with malfunctioning equipment. In many cases, the identified fault is the result of someone who was not trained to operate the machine, but was tasked to do so. It is often assumed a MCWP operators' task is simple: one button for up and another for down. This is absolutely not accurate, as the required knowledge to operate a MCWP safely demands specific knowledge. Authorizing someone who is not trained to operate or work from a MCWP without training can lead to accidents, lengthy delays, and unnecessary costs on site while incidents are investigated and machine breakdowns are repaired.

Training is crucial to avoid these hazards and guarantee the safe and effective use of this wonderful type of access equipment. If properly planned for, trained operators will ensure this equipment is a safe and effective way of carrying out all manner of work tasks at height.

If you have any queries about using MCWP, lift, and hoist equipment, or to enquire about IPAF’s training program, visit www.ipaf.org/contact to find details for your nearest office or representative.