FA Wilhelm Construction chose the Doka Top 50 formwork system because it could accommodate a variety of shapes and sizes the Omni Loisville required.

FA Wilhelm Construction chose the Doka Top 50 formwork system because it could accommodate a variety of shapes and sizes the Omni Loisville required.

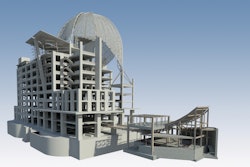

Building the Omni Louisville hotel which features nontypical floor heights and intersecting towers.

The players:

FA Wilhelm Construction

The process:

Scheduled to open in late spring 2018, the Omni Louisville is designed with intersecting towers that represent the crossroads of the past, present and future of Louisville, KY. The 612-room luxury hotel will transform one of Louisville’s most significant urban blocks into a unique and vibrant mixed-use environment offering both hotel guests and locals a chance to connect and enjoy the best of a great city. The hotel will be a prominent landmark against the Louisville skyline, glistening during the day and glowing at night.

Framax Xlife universal panels in use during column construction.

Framax Xlife universal panels in use during column construction.

The Top 50 large-area formwork system could accommodate the variety of the structure’s shapes and sizes. It can be assembled in any configuration to suit unique jobsite specifications, such as nontypical floor heights. The Shaft platform and associated formwork are quick and easy to position, with telescoping shaft beams that allow easy adaptation to any dimension. Universal panels from the Framax Xlife “construction kit”, with adjustment in 2-inch increments were used to construct the variable dimensioned column cross-sections up to 42 inches wide. The Framax Stripping Corner enables quick stripping of formwork.

FA Wilhelm Construction was able to move forms from floor to floor without needing a crane, which helped save time during construction.

FA Wilhelm Construction was able to move forms from floor to floor without needing a crane, which helped save time during construction.

“The Doka Super Climber is a safe and quick core system that is helping us achieve our required cycle times on this project,” said Joe Popp, project superintendent, FA Wilhelm Construction. “We are able to safely cycle the forms from floor to floor with minimal manpower and without the use of a crane. The forms strip out great in the corners and leave a quality finish.”