Early in 2021, construction companies needed to hire an additional 430,000 craft professionals. Additionally, the AGC found that 89% of contractors had difficulty finding skilled workers and that 88% of firms were experiencing delays.

Because of these challenges, combined with others presented to the construction industry in 2022, it’s safe to assume the skilled labor shortage is here to stay well into 2023 and beyond.

The good news is that there are workers, just a smaller number of them. Now more than ever, there needs to be a more consistent and streamlined process put in place to ensure that the workers you do have can achieve your project’s goals.

Determining where to place your crews and how to manage them not only assists with project deliverables but also helps your crews manage the work and flow of the jobsite, allowing them to be more productive and inclined to remain a part of your team.

So, what can you focus on to make project teams successful while also elevating project success? Crew logic. Let me explain.

In a recent webinar with AACE International, we kept pointing out the importance of crew logic, or as we sometimes call it, “The Silent Killer of Construction Scheduling.” Sure enough, we received a plethora of questions about what crew logic is, which to us was not a surprise.

What people are familiar with, though, is scheduling. Construction scheduling is an essential part of every project, of any size, and its success or failure largely depends on the proper allocation of resources. How these resources are allocated hinges on the logic within the project schedule. Therefore, the logic put into your project schedule needs to be consistent with what is feasible, not just with what is desirable.

Types of Logic within a CPM Schedule

Before getting into the nitty-gritty details of crew logic, I should explain the importance of rational logic in CPM scheduling. Critical Path Method (CPM) Scheduling develops a comprehensive work plan that shows how activities will get done within a construction project using network diagrams. The main benefit of using a CPM schedule is its ability to identify relationships and dependencies between all activities within the entire project network, thus creating a blueprint for project performance.

The relationships within this network are referred to as logic. Logic is the reason CPM scheduling programs can run calculations as it explains the order of the program, which is sometimes referred to as the project roadmap. This order is how the program calculates float values, start dates, finish dates, and so on.

It is critical for schedules to be built with quality in mind and high-quality construction schedules ensure that all the logic within them is accurate. However, the first schedule created often has incomplete logical information.

What does this mean? Within CPM scheduling there are two kinds of logic: hard logic and crew logic.

All About Hard Logic

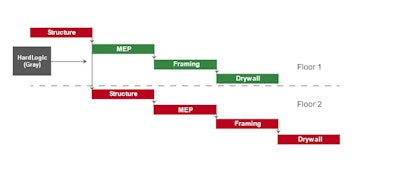

The first schedule created usually has accurate hard logic information, meaning the project scheduler has thought about what is physically possible according to the flow of things that need to get done. Hard logic represents logic that cannot be done in any other way.

The hard logic in this CPM schedule is explaining that you cannot begin Mechanical, Engineering, and Plumbing (MEP) work on floor one until you have completed the structure on level one.SmartPM Technologies

The hard logic in this CPM schedule is explaining that you cannot begin Mechanical, Engineering, and Plumbing (MEP) work on floor one until you have completed the structure on level one.SmartPM Technologies

The hard logic in this CPM schedule is explaining that you cannot begin Mechanical, Engineering, and Plumbing (MEP) work on floor one until you have completed the structure on level one. Similarly, you cannot start the structure of the second floor until you are done with the first floor’s structure because you cannot build on thin air; you need the structure below to do so.

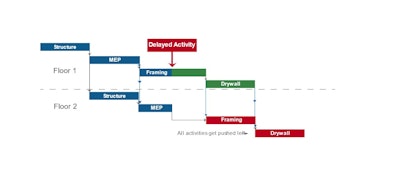

Hard logic represents how project schedules are wired. But, what happens when an activity gets delayed?

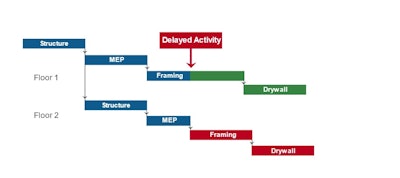

The schedule above depicts that the framing activity on the first floor was delayed.SmartPM Technologies

The schedule above depicts that the framing activity on the first floor was delayed.SmartPM Technologies

The schedule above depicts that the framing activity on the first floor was delayed. And, without crew logic present, the schedule is indicating that framing on the first and second floors is going to happen simultaneously, otherwise known as trade stacking. The issue here is, without an additional crew, the framing activities would be impossible to complete within their time parameters.

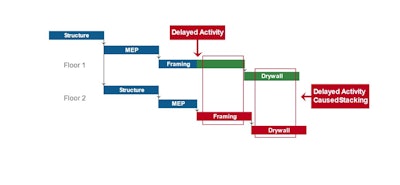

Trade stacking on top of delays does not reflect a feasible reality, especially considering the overbearing amount of resource and crew restraints happening in the built environment right now.SmartPM Technologies

Trade stacking on top of delays does not reflect a feasible reality, especially considering the overbearing amount of resource and crew restraints happening in the built environment right now.SmartPM Technologies

Furthermore, trade stacking on top of delays does not reflect a feasible reality, especially considering the overbearing amount of resource and crew restraints happening in the built environment right now. Additionally, when activities automatically stack on top of each other, float becomes consumed. And, when float is consumed, everything becomes compressed by design.

When everything is compressed, inefficiencies result, especially when you do not add people and are not sure if the area (or trade) is truly critical or not. This is where missing crew logic becomes “the silent killer.” So, now let me explain what crew logic means and why it is crucial for project success.

What is Crew Logic?

Crew logic is a form of “soft logic” that assigns relationships to activities that are reflective of where a crew is going to move next, based on means, methods, and crew constraints. For example, you might want your crew flowing from floor to floor or area to area.

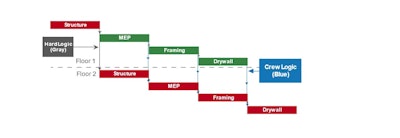

Let’s take a look at the same original project schedule with the same hard logic, but this time with crew logic added to it:

Now, the schedule has crew logic (featured in blue) embedded within it. The crew logic notifies the scheduling program that, for example, you cannot start framing on floor two until the framing is complete on floor one.SmartPM Technologies

Now, the schedule has crew logic (featured in blue) embedded within it. The crew logic notifies the scheduling program that, for example, you cannot start framing on floor two until the framing is complete on floor one.SmartPM Technologies

Now, the schedule has crew logic (featured in blue) embedded within it. The crew logic notifies the scheduling program that, for example, you cannot start framing on floor two until the framing is complete on floor one.

Why is Crew Logic Important?

Crew logic identifies crew constraints reflected in the plan, makes the schedule more reactive, and generates a more reliable and accurate critical path. You know, because the program is telling you, that you cannot begin framing on the second floor until it is finished on the first floor.

Crew logic identifies crew constraints reflected in the plan, makes the schedule more reactive, and generates a more reliable and accurate critical path.SmartPM Technologies

Crew logic identifies crew constraints reflected in the plan, makes the schedule more reactive, and generates a more reliable and accurate critical path.SmartPM Technologies

Without it, when an activity gets delayed, it overlaps with other activities on different floors. This means you will need additional crews to complete the stacked trades, which would otherwise get lost in the schedule file unless the PM and Super were paying very close attention.

Again, considering the skilled labor shortage, the multiple crews required to keep up with the plan may not be feasible. Basically, if you are not keeping a close eye on these things, your project will be delayed – and not just by a week or two. However, at the end of the day, delays happen, especially nowadays; they are essentially inevitable. That being said, it is how you handle delays that matters most.

Discussing Delay

This might seem contradictory to many people. After all, who wants to talk about delays when a great deal of money is on the line? I do, and so do many others to whom I have proved that discussing delay makes things much easier in the long run. Why is this?

Personally, I believe scrambling at the end of the job causes too much harm: mentally, emotionally, and physically. Not just for one person either, but for everyone involved. I also do not believe in sending out a schedule that says I am going to achieve something that I cannot. Rather, I want the program that I am using to tell me exactly when a delay happens so I can have conversations with relevant stakeholders about it to figure out the plan for mitigation. Or better yet, use the schedule as a tool to show trade contractors the delays and the consequences of the delay.

On the other hand, if you do not discuss the delays and just keep moving down the line, your schedule becomes compressed and potentially unachievable. Schedule compression comes with a lot of risks, including but not limited to the following:

- Poor schedule quality and viability

- Inefficiencies to trades

- Further delays and overruns

- Claims and disputes

- Impact on quality and safety

Creating a Reactive Schedule

Without crew logic, impacts are not clear. Trades become stacked by design, critical paths shift, and float becomes consumed - all of which are a recipe for delays, inefficiencies, and future disputes.

Essentially, crew logic makes the schedule much more indicative of when impacts are happening and the immediate effect of those impacts. This not only helps right the ship before it is too late, but it also aligns with your crew’s own constraints.

Most importantly, your crews are not merely resources. They are people and, especially in today’s environment, are certainly not expendable. If you take the time to know precisely what your crew teams can accomplish along with their plan to be successful, then implement that information into the schedule, your project will inevitably run smoother.