Technology continuously evolves and updates, giving us new and improved features, in some cases, every year. The heavy equipment industry has also experienced a steep evolving curve thanks to its integration with the internet, A.I., and automation.

Whether you like it or not, the fast-paced rhythm in which heavy-duty machinery changes makes older fleets “obsolete” in one way or another, even if they are still within their lifespan.

Modern fleets (as any other new equipment) have the advantage of less maintenance, at least not until years later. So while new equipment costs more upfront, it ultimately saves your company money long-term.

They are also more efficient due to unique technologies like hybrid systems, telematics, fuel economy, payload weighing, and grade controls.

On the other hand, outdated equipment, especially those past its lifespan, requires frequent repairs. There’ll be a point where expenses and downtime surpass the machine's profitability. But moreover, outdated equipment isn’t the best impression to attract clients.

If you’re already updating your fleet, consider doing it in its entirety or most of it because projects measure the usefulness of heavy construction equipment in hours of operation, miles driven, or cycles completed. An older asset might lag behind its newer counterparts, affecting the project’s rhythm to comply with milestones.

When to Consider Transitioning to Newer Equipment

Construction machines are movable mechanisms subject to heavy-duty jobs. Their components experience friction and stress over accumulated hours of operation, which lead to degradation (worn-out gaskets, corrosion, degraded electrical wiring, etc.) and, ultimately, failure.

Frequent downtime due to repairs or maintenance would be the first sign to consider retiring old equipment. The second sign goes hand in hand: higher replacement part prices.

Manufacturers and suppliers discontinue spare parts for older models. This limited availability makes it challenging to source replacements, leading to extended equipment downtime. The hard-to-find parts will also be more expensive base on the supply and demand economic model.

The third sign has to do with safety. Outdated (and inevitably malfunctioning) equipment increases the risk of struck-by accidents, a leading cause of fatal injuries and the most significant contributor to nonfatal injuries in the construction industry, according to a publication from the Data Bulletin.

Human errors are also maximized using old construction machines due to the lack of visibility because of large blind spots and insufficient aids like cameras, mirrors, and proximity sensors, especially with backing-up maneuvers.

How to Choose the Right New Equipment

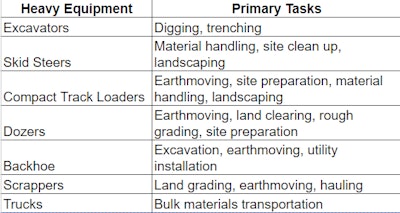

Although every machine can do several tasks, each specializes in one or two. Here’s a brief list of primary tasks for some of the most common types of machines:

Attachments will broaden the tasks machines can do. The availability of attachments, spare parts, and after-sale service should also be factors when choosing new equipment.

The job site will also determine your selection. Wheeled vs tracked, power vs maneuverability, fuel, electric, or hybrid.

Of course, there’s the total cost consideration, which includes the purchase price and the expenses associated with owning and operating the equipment over its lifespan.

By choosing prime equipment, you’ll minimize lifespan expenses, also ensuring a good resale value, another factor to consider when buying new equipment.

But a top-notch and popular brand of equipment will eventually need replacements. Consider high-quality parts, such as "OEM certified skid steer tracks," from companies like Fortis HD to maintain the depreciation low and the resale value high.

A couple more considerations when choosing new equipment are:

- Be open to buying used.

- Size matching units.

Equipment doesn’t have to be brand new to get the job done. You can update your fleet while lowering the upfront cost, but check warranties, liens, weldings not performed by OEM, operating hours, maintenance history, etc. If you’re considering this strategy, check out our article about six great reasons to buy used heavy equipment.

Lastly, acquire equipment of the same size within your fleet, as it allows for better coordination and efficiency in completing tasks.

Managing the Transition Process

The financial aspect is one of the first to consider and manage when transitioning from old to new equipment.

You’ll have to evaluate the impact on the overall budget due to the initial purchase price and long-term costs — maintenance, repairs, fuel consumption, insurance, and disposal. Compare the costs with the projected benefits and savings to evaluate the return on investment (ROI).

Explore and compare financing options — loans, leasing — to manage cash flow and minimize the initial financial burden.

Consult with experts about tax implications and assess the potential resale value.

The changes in your fleet will require adaptation, so plan the transition accordingly if you integrate new equipment while on an active project. Schedule it to overlap old and new equipment to ensure continuity of operations for minimal impact on project timelines.

Your operators will need comprehensive operating and maintaining machine training and hands-on practice.

Once they get the hang of it, consider a phased approach to the transition, starting with a pilot project or a subset of equipment before scaling up to an entire fleet transition.

Disposing of Old Equipment

We’ll focus on three options for disposing of old construction machinery.

First, direct selling. You can get as much as possible from the initial investment by selling the equipment. Setting the selling price is both a pro and a con (overpriced or underpriced). Research thoroughly before pricing the machine. Selling requires effort and time, but there are a couple of ways to ease the process:

- Online Marketplaces

- Local equipment dealers

- Auctions: events where construction equipment owners sell used machines to the highest bidder

A trade-in frees you from everything related to the negotiation since a dealer handles the transaction and paperwork.

A downside of trading in is that the dealer also assesses the equipment’s value by considering refurbishment costs, resale price, profits, etc. Thus, the trade-in value is lower compared to direct selling. Another con is that the dealer’s inventory is typically limited for your purchase.

For those machines beyond repair, recycling is the appropriate disposal option. It ensures compliance with environmental regulations, and you’ll still get some profits, although lower than selling or trading in.

Conclusion

If your current fleet shows signs of obsolescence, consider updating it before depreciation increases to maximize its resale value.

Once you thoroughly analyze what type of machine you need, refresh your company’s image and stay ahead of the competition by getting modern models leveraging their technologies to boost efficiency, productivity, and safety on your upcoming projects. And to minimize the upfront purchase cost, consider options like selling, trading in, or recycling your outdated equipment.

Keep your new equipment in peak condition to extend its lifespan and get the most out of it by scheduling a maintenance plan. You'll find helpful this comprehensive guide to properly service mini excavators, skid steers, and compact track loaders within your modernized fleet.