Check out the video from the MINExpo show floor right here:

At MINExpo 2021 Caterpillar has unveiled a first-of-its kind underground mining loader. But the thing about going to a show full of new mining equipment is that beyond doing a lot of looking up at the giant machines on display, you also get to look into the future.

The future as it pertains to construction equipment at least.

The new R1700 XE Cat unveiled Monday is a battery-powered loader. And while a battery-powered machine of this size that does the type of work this machine does—in the environment it does it in—is a huge deal, perhaps even more significant is the charging system Cat has developed for it.

That's the MCE500, a mobile fast-charger that Cat says is capable of charging up an R1700 XE in 20 minutes—yep. 20 minutes. You can’t even charge a Tesla that fast.

RELATED: This Excavator is Powered by a Motorcycle Battery

That’s a game changer level of advancement for electrification—regardless of what market or industry we're talking about. And you’re probably asking how it’s even possible. And we’re definitely going to get into that.

Because while a battery-powered R1700 XE will make a huge impact on mining operations around the world, we’ve also seen trickle down effect over the last 10 years or so, as technology developed for mining sites and equipment has made its way into construction sites and equipment.

So, the R1700 XE could be a preview of a major paradigm shift in how heavy equipment is developed, sold, powered and serviced.

A Proven Platform, Improved

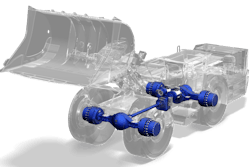

Before we get into all the juicy battery details, let’s get some basic information out of the way. The R1700 XE is built on the same platform as its predecessor, the R1700G. It’s got the same linkage geometry, the same 16.5 tons of payload capacity and the same 11 mph top speed.

In fact just about all of the common components on this machine from the articulation joint forward are the same as you’d find on the G-Series version.

But it’s not all carryover. For starters, Cat has made changes to the chassis of the machine to improve durability, they’ve revamped the component positioning, and they’ve made improvements to the cab including a new HVAC system and reduced noise and vibration levels.

The Battery

OK, but what about that battery? Well, right here in the back of the machine is a lithium ion phosphate battery pack that Cat says has a 210 kWH capacity. It’s maintenance free, fully enclosed and liquid cooled, offering FOPS Level 2 protection.

Just for reference sake, a Tesla Model S can be equipped with a 100 kWh battery, while the new GMC Hummer packs a 200 kWh power unit.

Cat isn't actually developing or manufacturing the battery cells or technology behind those cells. Instead they're sourcing battery cells and focusing on the work of developing the appropriate rugged packaging for those cells.

"We don't typically name who is actually sourcing the battery cells themselves. But the first thing we looked at ... is understanding the requirements of an underground environment," said Cat's David Rea, general manager of Cat Hard Rock, Underground Vehicles and Large Trucks. "While we don't produce the batteries themselves, we work in terms of how you string them together, how you package them, how you cool them, how you maintain them,and it's integrated into our technology strategy in terms of how it's all managed.

"And it's important to maintain that focus on the overall performance so that as battery chemistries evolve, as battery technologies evolve, we're able to facilitate changing of the battery technology but still within the same performance, safety, reliability envelope that we've designed on the machine.

Cat says the battery can keep the R1700 XE digging deep beneath the surface for anywhere between 2.5 and 4 hours—it all depends on how hard you run the machine. But wait, you’re probably thinking, 2.5 to 4 hours? That’s it? That’s not nearly enough runtime.

Well, Cat agrees with you. Which is exactly why they created the MEC500.

Revolutionary Fast Charger System

This is a first-of-its-kind 500 kWh charging unit that provides on-board charging for the R1700 XE. Think of it like the heavy equipment equivalent of the portable battery pack chargers we tote around to top up our phones and tablets.

Rather than having you swap out the actual battery pack in the R1700 XE, the 3,500-pound MEC500 can be lifted, lowered or drug into position right alongside the loader. Once the MEC500 is in place, you connect the charging cable to the machine and power it on with the press of a button.

But here’s the kicker. Cat has made it possible to connect two MEC500 units to the R1700 XE at the same time, providing a full recharge in about 20 minutes.

In fact, even if you only connect one MEC unit, it still recharges the machine in 30 minutes or less. And you can keep track of your remaining time left in the recharge with an easy-to-read color display on the unit.

With 500 kWh of capacity on board each MEC unit, there’s enough power in each of these mobile batteries to recharge an R1700 XE twice.

"But in fact in some cases, we've actually seen us go an entire shift without a charge cycle,"

That's thanks to what Rea called "opportune charge times," where operators connect the MEC500 to the R1700 XE anytime they're on a break or there's a work stoppage. Sometimes that's 20-30 minutes and enough time to fully recharged the machine. Other times, it's only 3 or 4 minutes—but 3 or 4 minutes means a 10-20% boost in remaining battery.

"It's amazing to see a couple of those quick top ups and you can just keep on working through your shift," Rea said.

Beyond the fact that a mobile fast charger that gets you up an running in less than 20 minutes is just plain cool, it’s also less taxing on a mine site’s infrastructure.

That’s because it doesn’t require the site to come up with a solution for ferrying batteries back and forth between the machine before doing the work of swapping them out. Plus, it doesn’t require the site to install a dedicated charging bay for the machine.

Plus, it can also mean big savings for a mine site's ventilation needs thanks to the machine's elimination of emissions and heat.

"One of the most significant costs to going deeper is in your ventilation and the investment in keeping cool, clean, fresh air going underground," Rea said. "A zero emissions battery machines significantly reduces the amount of ventilation required which in some cases now makes non-viable assets, viable."

Instead, you simply connect the MEC units to your existing electrical infrastructure to charge them up and then drop them wherever they’re needed.

Hybrid purchase option

With this innovative new machine and charger package, Cat has also come up with a new way to purchase or lease this equipment.

You can buy the machine through Cat Financial and then lease the machine’s on-board battery separately for a certain time period. Once that period is up—usually around two years—Cat actually removes the battery, swaps in a new one and and recycles the old one. Cat is also providing financing support for the MEC500 charging units.

A Surprise Peek at the Future

I’ve covered electric heavy equipment pretty extensively over the past few years and, honestly? I didn’t expect to see a solution like the one Cat has put together here for the R1700 XE to hit the market so quickly.

This is a truly astounding piece of engineering and represents just one more way that electric machines could be deployed and powered in the near future—not just on mining sites, but on construction sites as well.

Because if a 210 kWh battery can provide up to 4 hours of runtime for a machine that works as hard as this one, it can very likely power a wide range of equipment aimed at construction for that time period as well.

And that 4 hour runtime hurts a lot less if recharges only take 20 minutes or so. But I’d imagine that by the time this technology hits construction machines, battery life will be even better and charging times even faster.

Also worth mentioning on the MEC, Cat plans to build support into this charging unit for other machines. So, eventually you’ll be able to use these packs to power all sorts of equipment.

"We believe this charger can be used on non-Caterpillar machines as well and that the customer will be able to leverage it for other fleet that they have," Rea said. "We don't produce a drill, but they could utilize our charger if that drill is electrified."

The R1700 XE is currently still in testing and development stage, with three units deployed to mining sites in Canada—one of which has 1,000 operating hours under its belt. Cat is also planning on including automation features with a factory-ready package around that technology.

The R1700 XE and MEC500 charging units are slated for release in early 2022.