Just like when operating cranes, understanding how to read load charts, and applying that information to the operation of a digger derrick is critical. In many ways, digger derricks are similar to cranes with telescoping and rotating booms, jibs and other attachments, and winches with load lines that can be configured with multiple parts of line. Applying this knowledge will help with safe operation of the equipment and taking the written test to become a CCO-certified digger derrick operator. An important part of the overall written exam score relates to load charts.

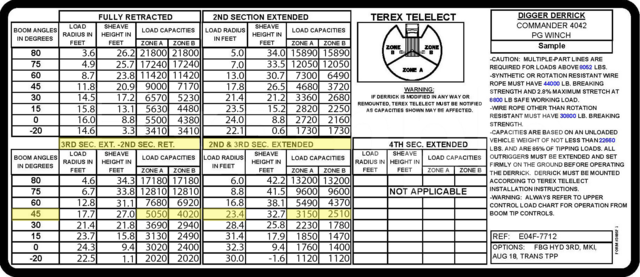

Digger derricks load charts are designed specifically for the unit serial number of the unit. That means that just because you have more than one Terex Commander 4042 in your fleet, the same load chart may not be used for both units. The nature of the industry is that digger derrick capacities are directly affected by the chassis the digger derrick is mounted on, where it is mounted, the options and accessories the digger derrick is equipped with.

While load charts are affixed to the device in view of the operator near the controls, it is critical to always verify that the serial number on the load chart matches the serial number of the unit. The load chart for that unit takes into consideration all the options installed on the boom when the digger derrick was built. If additional options are added to the digger derrick that increase the weight of the booms, a new load chart must be created to account for this additional weight.

Important Terminology

The rated capacity of the digger derrick is the maximum working load permitted by the manufacturer for the boom configuration and boom position. Such boom position factors include load radius, boom length, boom angle, and other parameters of use. The rated capacity will be different depending on where in the load chart you are working, how many parts of line are used, and other factors such as type of rope installed.

To begin, below are some important terms every digger derrick operator must understand.

Load Radius: The distance from the center of rotation of the digger derrick to the center of gravity of the load.

Gross Capacity: The maximum weight that a machine is designed to lift, which includes the load, attachments, and all rigging. This corresponds to the value found on the load chart.

Net Capacity: The maximum weight that can be lifted.

Net capacity is calculated by reducing the value found on the load chart by the weight of the rigging and added attachments. Net Capacity equals gross capacity minus all lifting deductions (rigging and attachments). The maximum weight of the load cannot exceed the net capacity.

Determining the Load

When teaching this concept to students, I compared it to their paycheck. There’s their Gross Pay. Then there are taxes, insurance, and other deductions that leave them with their Net Pay. Just as Net Pay is what you get to spend, Net Capacity is what’s leftover that you can actually lift.

Now, let’s talk about the load. You have to consider more than just what the transformer, pole, or cable reel weight, which is the Net Load. Gross Load is the total weight of the transformer, pole, or cable reel plus the weight of the rigging. You must consider anything that is suspended on the load line as part of the gross load—shackles, slings, etc. So, while Net Capacity is key, it’s Gross Load that is important. The total weight of the load, attachments, and rigging must stay within the capacity shown on the load chart.

The Terex load chart displays the gross lifting capacity. It is based on the options at the boom tip and the auger being stored on the main boom. The auger size is listed as an option on the load chart, so operators know what was included when the chart was created. If they increase the auger size, they now need to deduct the weight difference from their gross capacities. If they do not want to make the deduction each time, a new load chart would be required

A Moving Target

Load charts show information about the Gross Capacity the digger derrick can lift given various criteria. For example, whether the boom sections are extended or retracted, what the boom angle is, as well as which zone you are working in. Terex digger derricks offer two zones representative of lifting either over the side or the rear of the truck. It is not recommended to lift over the front of the cab.

In this example, a specific Commander 4042 is set up with the third boom section extended and the second boom section retracted and with the boom at 45°. The digger derrick can lift 5,050 lbs. in Zone A and 4,020 in Zone B. However, when both boom sections are extended, the load radius goes from 17.7 feet to 23.4 feet. Gross capacity is now 3,150 lbs. in Zone A and 2,510 lbs. in Zone B.

Because the allowable load may change based on path of lift it is important that operators plan out the intended load movement from picking to setting. Maybe you are picking a transformer off a trailer parked behind your digger derrick, intending to rotate to the side and lift it to the top of a pole. Your lifting zone, load radius, boom angle, and number of boom sections that are extended will change through the full lift as the load moves from picking to setting. Always make sure your capacity is sufficient through the entire range of motion and various boom positions.

In addition, some companies may have policies that require digger derricks to operate within a certain percentage of maximum capacity. Make sure you factor that in when planning your net capacity and gross load weights.

Load Lines

Load charts also provide important information about the load line. Different types of load line have different capacities. The load chart provides information of the line working load limit required. When replacing ropes follow the information on the load chart for rope strength and elongation. Always replace the rope with equivalent type, synthetic or wire, and capacity. The rope length must be long enough to reach the ground in the intended single or multipart configuration.

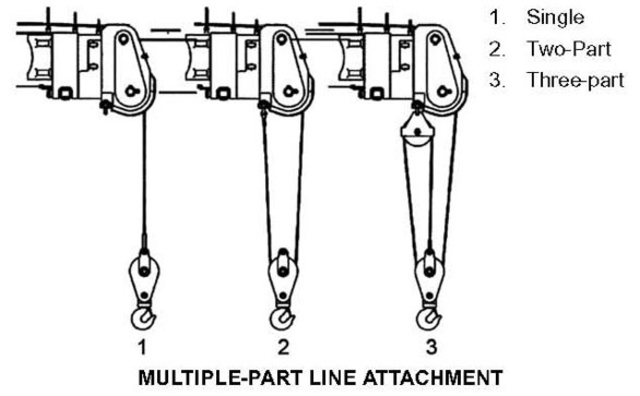

The number of parts of line is critical to the capacity of the line itself. Digger derricks are frequently used with a single part of line. But loads that weigh more than the amount shown on the load chart for single part capacity, require that the load line is set up for multiple parts of line as needed for the load. There is a mechanical advantage to having multiple parts of line, as multi-parting the line does not increases the capacity of the load line but allows higher loads for the digger derrick up to the load chart capacity. In the example shown, the single part load line capacity is 8,052 lbs. If you are lifting a load greater than this, and still within unit gross capacity, you will need to multi-part the load line. Two parting will give you 16,104 lbs., three parting will allow 24,156 lbs., as long as you are under gross capacity of the digger derrick.

Handy Tools and Final Reminders

All of this is well and good, but if you don’t know the weight of the load to be lifted, the planning is worthless. Some digger derricks are equipped with load line indicators. If not it’s an easy and good practice to use a dynamometer to measure the weight of unknown loads. Since 2018, Terex Utilities has offered its Load Display option on Commander digger derricks as an operator aid.

The load cell measures the actual load on the winch line, which is then shown on the display at the control station, to assist operators as they follow the load chart. The load cell attaches between the winch line and the hook and wirelessly transmits the value to the display. It is available as a 6-ton system for single line capacity. If multiple parting the line the actual load must be calculated based on the number of parts of line used times the value displayed.

Finally, one last reminder. While digger derricks and cranes have a lot of commonalities when it comes to understanding load charts, there is one critical difference. Digger derricks require that the outriggers are correctly deployed. Cranes may allow for on rubber or partially extended outriggers. Terex Utilities equips its digger derricks with an outrigger interlock, which prevents boom operation if outriggers are not deployed. The actual setup and outrigger adjustment can only be performed by the person at the work site. Make sure to properly position the digger derrick on firm, level ground and set the outriggers as per the Operators Manual on outrigger pads before beginning operations. If the digger derrick is not level the capacity is reduced.