Formwork is one of the most costly, labor-intensive and time-consuming phases of the concrete construction process. Under increased pressure to complete projects on time and budget, rethinking how formwork is planned can help concrete contractors outperform the competition, work more efficiently and meet modern project demands.

There was a time when drawing or copying and pasting CAD blocks in 2D was the only way to create formwork layout plans. Even today, as much of the construction industry has adopted 3D modeling, many concrete contractors continue to rely on information and documents produced using 2D CAD. With his approach, formwork is disconnected from other construction-planning tasks, resulting in a lack of information and errors.

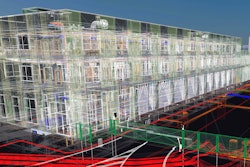

Whether on paper or a computer, using 2D to plan formwork increases the potential for error, guesswork and risk. It’s impossible to capture and deliver all of the information of an actual, three-dimensional structure in 2D. For example, 2D can’t reflect all aspects of a project as they exist in real life. When relying on 2D, the information needed for timely, high-quality formwork planning is often low-quality or missing from design drawings altogether. What’s more, 2D makes it difficult to spot potential errors before they turn into costly rework. Using tablets, installation teams can access 3D formwork models and associated, up-to-date information and documents in the field.Tekla

Using tablets, installation teams can access 3D formwork models and associated, up-to-date information and documents in the field.Tekla

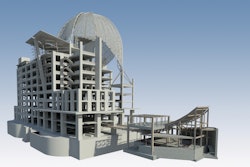

Improving Formwork Planning and Detailing with 3D

For concrete contractor F.A. Wilhelm, working with a constructible 3D model has increased accuracy and accelerated formwork planning.

“We use Tekla Structures as a single solution for our formwork detailing, planning and project execution," says Adam Joraanstad, formwork detailer. “We can estimate, design and plan our formwork more efficiently and discover potential pitfalls earlier on in the process.”

Moving from 2D CAD to 3D can take formwork planning to the next level and open the door to more efficient, accurate and productive projects by:

- Automating takeoff: 3D modeling allows for instant material takeoffs and automatically provides correct areas for different formwork types during planning and estimating. When using BIM, the model and takeoffs are connected, meaning that formwork area quantifications can be visualized in 3D and organized according to location, pour type, sequence and planned formwork type. This allows contractors to include formwork line items in budgets for more accurate, reliable estimates.

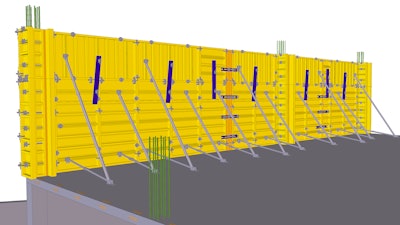

- Streamlining processes: With effective modeling tools pour geometry can be modeled and used to allow for placing of formwork components and accessories, such as ties and clamps automatically. And, because all reports and drawings are generated from the model, and changes are automatically updated to all documents, the risk of human error is significantly reduced compared to manual, disconnected 2D workflows. Creating a model with detailed and constructible information means contractors can proceed quickly and securely to the construction phase, with far less manual work.

- Assessing Constructibility: Rather than discovering problems in the field when it’s too late, 3D visualization makes it easier to detect clashes and resolve potential constructability issues early in the process. With a 3D model the question, “can we build this?” can be answered at a glance. Similarly, pours can be planned and construction quality quantities automatically reported just by adding pour breaks to the concrete model.

- Communicating requirements to the field: 3D models help everyone on site quickly and easily understand formwork requirements. Using tablets, installation teams can access 3D formwork models and associated, up-to-date information and documents in the field. Having this information readily available removes any guesswork and greatly reduces requests for information, unproductive work and the potential for error. It also makes it easier for contractors to ensure that construction work is progressing as planned.

Looking Ahead

The concrete industry is becoming increasingly competitive as a growing number of contractors adopt tools, such as BIM and collaboration platforms, for managing project information. Those still using traditional methods might be comfortable today, but as their competitors complete bids and projects faster, easier and with better accuracy and quality, they will soon find that it’s time to catch up.

Moving to 3D formwork planning and detailing opens the door to working smarter and faster. With 3D formwork planning, concrete contractors can create formwork drawings, deliver the right information to workers in the field and spot problems before it’s too late. This allows concrete contractors to minimize risks, improve productivity and reduce construction costs through more accurate estimating and planning, efficient management of high-quality information and streamlined coordination and communication.

Written by Guy Erickson, business manager at Trimble, Structures Division.