On August 21, 2025, Milwaukee Tool invited just over 100 people from throughout media to attend its annual hands-on launch event. There were popular social media end-user influencers from all the trades in construction to landscaping (electrical, HVAC, concrete, and more) as well as long-form publications. The event was located in Milwaukee, Wisconsin.

As one of these lucky few to attend, here’s only a fraction of what I saw. Note: this article is not sponsored; this is merely a report on what was observed and announced.

The company has been dedicated to the skilled trades for decades. Many of the tools and improvements have been inspired by representatives travelling the country, visiting jobsite to jobsite, talking to contractors on active construction projects. They say, “We don’t just design tools; we co-create them with the trades.”

Milwaukee has also invested in the next generation of skilled trades. Together with partners, they’ve committed over $150 million toward training, safety education, innovation, and career access with a goal of having that investment reach $200 million by 2030 – that’s $10 million a year.

Prior to the event, attendees were witness to this commitment with the Wisconsin Regional Training Partnership (WRTP), a locally-based organization specializing in the development of hands-on, group-size pre-employment training certificate programs and the Building Industry Group Skilled Trade Employment Program (BIG STEP). Groups of students were given a plan to install various electrical and HVAC elements onto a pre-constructed framework. Each group worked at its own pace with a mentor to assist. A finished example accessible for anyone to investigate.

It was inspiring and heart-warming; the event was the first time many of the students held a power tool, let alone built something with their hands.

Hands-on

If you’ve never had the chance, here’s how the PIPELINE day is organized:

- The day typically starts with a presentation from brand managers and corporate leadership. We’re informed about the direction the company is heading in for the coming year and what to expect.

- The hands-on space was organized similar to a tradeshow with areas focused on relevant trades. For instance, one area focused on mechanical tools featuring an engine to allow people to use the tools in a familiar setting; concrete equipment had a display with a concrete mix to feature their vibrating screed; multiple outdoor areas allowed people to use outdoor power equipment; and more.

- The day wraps with a question-and-answer open forum, allowing the audience to ask any questions they have. Many take the opportunity to open their wish list and ask if there was something “in the works.” If my experience tells me anything about what’s going on behind closed doors, yes, someone has likely thought about it.

Note: I’ve attended PIPELINE a number of times now, and none of them have been exactly the same.

Milwaukee Tool

Milwaukee Tool

Notable Launches

After the welcome presentation, it was time to go check out the tools hands-on. The curtain walls surrounding us lifted, giving us a very literal opportunity to go behind the curtain.

(See what they did there?)

A lot of products were announced; here is only a fraction:

- Roll-On 7200W/3600W 6.0KWH Power Supply, launch date Q2 2026

- M18 brushless blower – handheld, launch date Q4 2025

- 8 lb. sledge hammer with a 36 in. handle – launch date Q1 2026

- 10 lb. sledge hammer with a 36 in. handle – launch date Q1 2026

- 5 lb. pick mattock with a 36 in. handle - launch date Q1 2026

- M18 FUEL rotary hammer with One-Key in 1 9/16 in. and 1 3/4 in SDS MAX – launch date March 2026

- Polarized and non-polarized wrap-around safety glasses – launch date Q1 2026

- Polarized and non-polarized full-frame safety glasses – launch date Q1 2026

- Full-brim Type 2 safety helmet

Touring Safety

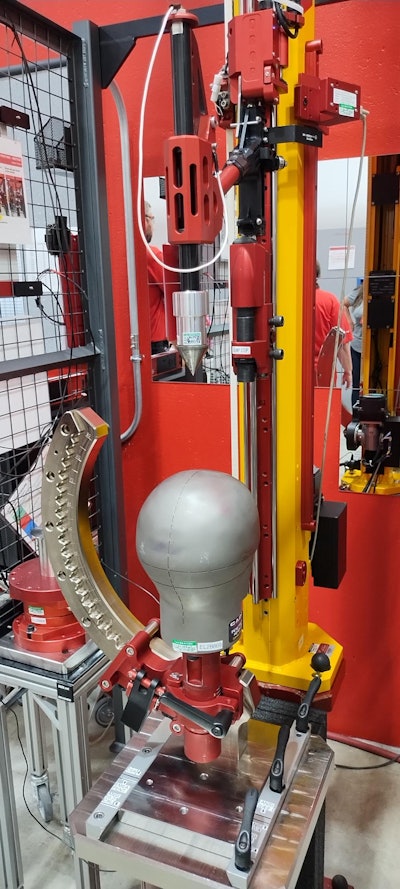

A handful of attendees were invited to attend a tour of the nearby facility where every Milwaukee Tool PPE and square and leveling products are manufactured. The group toured the PPE side. The area was part of a $5 million renovation, which included an expansion of the original building to accommodate the machines to manufacture the Bolt helmet line.

It marked the first time they opened their facility’s door to media— ever.

One of the helmet impact testing machines.

One of the helmet impact testing machines.

Samples from the line are taken to the quality certification room for testing. The area included freezers, ovens, water-based conductive tanks, as well as impact testing. In a typical month, the lab should test about 200 batches.