Few contractors know how to track job costs effectively. Very few. The reasons for their struggle are plentiful, but they start with a simple misunderstanding: The term "job costing" implies the goal is to track dollars, but what you really need to track is man-hours. As long as a contractor focuses on tracking dollars, he will never collect the type of information he needs to:

- Predict the cost of large projects accurately

- Achieve consistent on-time completion

- Persuade crews to work hard

- Accurately account for the impact of rapidly changing material costs

Small pavement maintenance contractors' job-costing systems should be built to track labor productivity - the time it takes field workers to perform their construction tasks. Few pieces of information have greater value to you than knowing the speed at which your crews work. Having that knowledge is like money in the bank. And the only way you get that knowledge is by installing an effective job-costing system.

KISS It

You need to use an easy-to-grasp approach. In other words, KISS it - Keep It Short and Simple.

Short means track the absolute minimum amount of information you need to make profitable decisions. Simple means your employees must be able to learn how to collect the data. You need to install a job-costing system that delivers the goods without being overbearing to your people. Difficult, but not impossible.

Cost Codes

When it comes to data collection, "more" is not better. "More" is destructive. Ask field workers to track too much data and they will revolt by recording useless data.

To keep data collection manageable, go after the tasks that account for 80% or more of the crew's time. You will discover that roughly 20% of the tasks account for 80% of the labor time. Those are the only tasks yours crews should be coding their time to. All time not associated with the 80% codes should be allocated to "Other."

Rule of thumb: An employee should be able to record all of one day's time to no more than six codes.

Consider the tasks a patching crew performs.

- Traffic control

- Saw cutting or grinding

- Removal

- Placement

- Rolling

- Clean up

- Mobilization

If your crew repairs three or four lots per day workers should track their time by three tasks: cutting and removing, filling and rolling, and mobilization. If your crew tends to spend a day on one lot workers should track their time by all of the tasks listed above. The right answer will differ by crew and project.

Once you've figured out which labor tasks to track, create a numbered list of the codes allowed for the job. Give the foremen a list of the codes complete with clear descriptions of what tasks are to be assigned to each code.

Tracking Work Output

In order to calculate labor productivity (i.e. the speed at which your crews work) you must know how much work the crew performs. Examples include square feet of pavement sealed, pounds of crack filler used (or lineal feet of cracks filled), number of stalls marked, tons of hot mix placed, square feet of parking lot swept.

Much of this data will come from the original takeoff. Quantities such as pounds of crack filler will need to be recorded in the field. Do not have field workers record data that can be captured in the office from existing documents.

Time Card Design

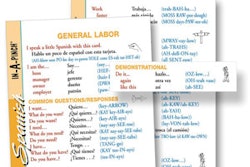

Make sure your time sheets are user-friendly. The less writing the foremen need to do, the better. Consider printing custom time sheets containing project information and material quantities for each job. You will soon discover that the easier the data recording, the better quality the data.

Critical Note: Time cards must be turned filled out daily! Data quality drops off rapidly when crews are allowed to fill out cards a few days down the road. Give each worker a pocket-sized spiral notebook to jot down their coded time throughout the day. Then they, or the foreman, can transfer their notes to the time sheet at the end of the day.

Crew Training

The final data collection step is teaching the field crews and foremen how to fill out the paperwork correctly. Give them examples. Have them fill out a couple of time cards together in your office. Provoke questions and answer them.

We all know how much the field workers hate paperwork. If they liked paper work they would have become desk jockeys. They didn't and they don't so you'll need to sell your employees on the value of the sending in accurate data.

Explain that the data is essential for setting realistic budgets and schedules. Explain that their personal financial security is tied to you knowing your costs. After you've answered the "What's In It For Me?" question, hold your foremen accountable for submitting complete and accurate time sheets. Job costing is not as important as safety, but it runs a pretty close second.

Data Storage & Analysis

You will find that storing your labor productivity job-cost data in a spreadsheet is by far the easiest way to analyze it. Export the data to Microsoft Excel or enter it directly into Excel from the start. Group and sort the data. Throw it into charts and tables (have someone set up Pivot Tables for you, they're the greatest for this task). Look for trends and averages. Update your estimating and schedule based on the conclusions the information reveals.

Conclusion

Job costing is a hot button with contractors - as well it should be. If a contractor can't tell whether he is making money on his jobs, he is going to get into financial trouble. The risk of job costing is that you can waste a lot of employee time collecting information that turns out to be worthless. To run a business that produces a predictable profit you must accept the headaches associated with collecting and analyzing job-cost data. Job-costing systems are very, very difficult to get right. But they are essential to survival in the construction industry!