The upcoming Infrastructure Investment and Jobs Act (IIJA) —a $1.2 trillion bipartisan plan is great news for our nation’s roads, bridges, airports, waterways and other infrastructure in desperate need of safety, congestion and connectivity enhancements.

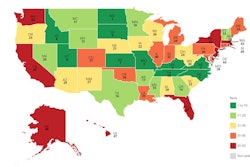

The bad news is that the construction industry is currently battling a widespread labor shortage. According to the Associated General Contractors of America (ACG), 89% of U.S. construction firms are struggling to hire workers, causing significant project delays.

So, with funding potentially on its way, firms already struggling to do more with less will now have to find a way to do even more.

The problem is daunting.

But the good news is there’s a solution; and it’s in the bill itself.

The call for digital technologies

In addition to funds for infrastructure repairs, the IIJA includes $100 million over five years to accelerate the deployment of digital construction technologies.

This is great news for the construction industry, which has lagged behind the rest of the automated world. For an industry that relies on the continuity of standards, little change tends to happen over prolonged periods.

But—finally—all eyes are on construction, and those standards are changing. Because without digital construction technologies, there’s simply no way the industry can keep up with the influx of projects to come.

The question on everyone’s minds: How do we do it without disrupting our workflows?

The road to automation starts with CMT

Public and private project owners have been charged with not only accelerating infrastructure development but enhancing public safety as well. And in construction, public safety starts with the integrity of the construction material itself.

Thus, construction materials testing (CMT) is an ideal place to start rolling out automation.

An automated CMT solution – one that uses both the appropriate software and testing machine hardware – allows project owners to replace manual tasks with automated ones. The result adds transparency to the process, making it easier to trust that the materials being used to build our infrastructure are meeting expected safety standards.

But it’s not just about the end-product. Automated CMT solutions will play a key role in helping firms support the anticipated wave of construction work. Let’s look at a few of the most critical areas.

Fewer errors and less inefficiency

Of course, the point of automation is to remove manual tasks. But let’s take a moment to see how automating something as niche as construction materials testing can impact the timeline of a project.

Think about every number manually entered on a spreadsheet; every test run on a manual machine; every specimen that must be labeled, transported and stored – all manually.

Each one of these tasks can be completed in seconds or minutes. But after hundreds or even thousands of tests, the time investment becomes more obvious.

What if the process of identifying a specimen was as simple as scanning a barcode? What if you could run a test at the press of a button?

Introducing automation allows technicians to spend less time on manual CMT processes and more time on tasks deserving of their skill level.

Working smarter, not harder

Testing cylinders is hard work, which means it’s also very manual. For every material specimen being tested, a lab technician must pull data on the material, identify the individual specimen, run the test, record results, and send data to the next stakeholder in the chain.

Given the number of manual tasks being completed, it’s not surprising that errors typically slip through the cracks.

Plus, with new employees in short supply, current employees are being overworked. This has a negative effect in areas like worker safety but also accuracy. Overworked employees make more mistakes, and are more likely to burn out and leave their jobs—making the labor shortage even more of a challenge.

Accurate data is trustworthy data

While automation in the construction industry is still in its infancy, it’s not brand new. Automatic testing machines, which have grown popular in recent years, allow labs to test with extreme precision. Pairing automatic machines with CMT software makes it easier for labs to collect and store data without human intervention – removing the possibility of specimens being mislabeled or tested on the wrong date.

In short, there’s simply no room for error.

Best of all, if questions arise about the validity of results, project owners can feel confident that CMT data was tested, checked, recorded and approved correctly; ensuring projects can move forward and stay on deadline.

A path forward

There’s a reason why so many other industries have turned to automation. And there’s a reason why the tentative infrastructure bill includes a budget for digital construction technologies.

Fewer manual tasks. Fewer stressed employees. More accurate results.

These qualities enhance not only the CMT workflow but also the entire project. Automating the CMT workflow is a required step for every construction firm struggling with today’s labor shortage—regardless of the life of this infrastructure bill.

Joel Simpson is the Senior Vice President, Sales & Marketing, for Forney LP, which offers scientific testing, measuring and processing instruments for the concrete, soils and asphalt industries worldwide. He also leads sales and marketing initiatives for ForneyVault, a cloud-based, integrated construction materials testing platform.