Safety on jobsites is the first thing that must be ensured on any kind of construction project, but never more so than when heavy machinery and equipment are being used alongside workers on the ground. Because of this need, safety managers have increasing numbers of new tools to enhance their safety plans and help better protect employees.

Advancements in sensors, radar systems, cameras and autonomous technologies are improving risk detection capabilities and, therefore, the overall safety of the jobsite.

However, to develop a successful safety plan, managers must be able to identify where hazards are likely to occur and how to overcome them. This data can be challenging to obtain without the correct digital infrastructure. Accidents and near-misses provide key insights for safety planners to put in place effective risk management strategies, but they are rarely reported by workers, and the heavy machinery itself can only be made more accident-proof if the most likely causes of accidents are identified.

This is where technology transformations can elevate existing safety plans. Systems that alert workers to potential dangers, improve the ability of the heavy machinery operators to sense their surroundings and collect this data for later analysis have proven highly effective in improving safety on jobsites. Incorporating this into developing safety plans can be invaluable in preventing fatalities, serious injuries and near misses.

Making Technology Part of the Uniform

Preventing accidents and near-miss incidents between heavy equipment and workers has become a focus for technology companies working in the construction sector. The primary aim is always to reduce onsite incidents that not only have, first and foremost, a huge personal cost but also a financial and reputational business cost.

Accidents involving individuals and heavy equipment are the biggest threat to workers and can have devastating results despite the best efforts of manufacturers and safety managers. Equipment of this scale will always have a blind spot, and the best way to avoid this danger is to prevent people from entering these blind spots.

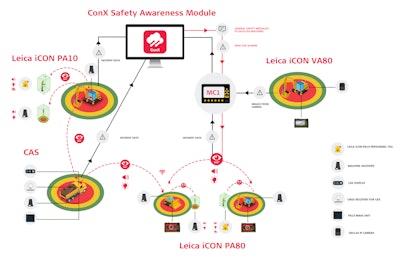

One solution to combat the blind-spot risk that could reduce these accidents is using a real-time awareness and alert system. This combines a sensor tag worn by workers on the ground which communicates with receivers installed in all the machines and vehicles on the construction site. This dual system provides machine-to-people awareness with direct notifications to the heavy machinery operators through visual and audio alerts to notify them of potential risks within a configurable radius of up to 50 meters.

On the ground level, wearable tags also have a panic button that can be pushed if the wearer is in distress, alerting all machines in range that something is wrong and work as usual must stop. Systems can also be configured to indicate no-go zones on the jobsite to alert operators that their machine is nearing an area they should avoid, for example, because it is guaranteed that a lot of people will be in that space throughout the construction project. As an additional preventive measure, if physical obstacles are onsite, such as potholes or tree trunks, these can be programmed into the system, ensuring that personnel are alerted to their presence and can avoid them. This system alerts the operator of a potential collision with a worker on the ground.Hexagon

This system alerts the operator of a potential collision with a worker on the ground.Hexagon

Harnessing Data for Future Safety

As well as minimizing immediate risk, technology transformations in construction also help managers improve safety in the long term by collecting the data generated by wearable tags and machine-mounted equipment. This can provide insights into incidents that go unreported, such as near misses, giving planners further opportunities to elevate their safety plan and improve their site’s safety culture.

With a logging system that can record long periods of movement, capturing position, speed, headings and alarms, this data provides a valuable snapshot into work behaviors and shows where the largest concentration of alarms are occurring on a site. This information may prompt procedural changes. All these data points can help companies evaluate and improve safety procedures.

The benefits of this data collection are not only physical but also psychological. The knowledge that this information is being gathered may change staff behaviors for the better. For example, changed behaviors may increase the likelihood that near-miss incidents are reported because ground workers can be reassured that their reports will be backed up by the data.

The next step will be incorporating the data into machine control systems and creating web-based interfaces that allow better user interaction with the data generated and collected, such as producing heat maps from incident reports to further reduce the gap between data collected and data leveraged.

Combining Technology Solutions for Optimized Results

Typically, safety systems are either sensor- or camera-based. However, more technology companies are combining systems and seeing significant benefits.

Cameras are commonly used on heavy-duty equipment because they offer increased visibility of a machine’s surroundings. However, they also require operators to watch the footage and the quality of their recordings is susceptible to lighting and weather conditions.

A safety awareness system with combined technologiesHexagon

A safety awareness system with combined technologiesHexagon

By partnering with other safety solution experts, collaboration between different technologies can take place for enhanced safety. For example, combining an alert system with dual-height sensor limitation, slew restriction systems, and height and rated capacity indication technologies can help prevent an excavator from lifting more than is allowed according to health and safety requirements or local legislation.

This dual integration adds an additional layer of safety to the alert system already provided. When a tagged ground worker or object is within a pre-configured alert zone, the appropriate personnel are alerted and the slew restriction systems can proportionately and autonomously slow down and safely stop the machine in question, reducing further risk of an accident.

This combination of technology means that employees are more protected, and the heavy machinery itself is more “aware” of its surroundings and better equipped to overcome the major safety challenges on a construction site. With autonomous technology such as this, it is essential that the machinery is as aware as possible of its surroundings to be able to work efficiently and safely.

Looking to the Future of Safety

With the rate of technological advancement increasing over the past decade, existing solutions to elevate jobsite safety will no doubt improve, and new solutions will continue to emerge. Companies are already working on incorporating augmented reality (AR) into their safety plans in a way that allows operators to see through machines to avoid collisions or running over any objects. Artificial intelligence (AI) will also play a significant part in advancing autonomous technology solutions, for example enabling autonomous machine driving powered by more reliable, human-equivalent reactions.

The possibilities presented by technology transformations in elevating safety are vast. These include introducing wearable tags, combining technology solutions, the near-future potential of AR and AI, and analyzing the data generated by these technologies. As the industry moves forward, technology will elevate safety by improving awareness and reactions of the individual, the machinery and the software.

Safety is the priority for any construction project, and understanding the cause of hazards is key to adopting the right solutions and reducing risk. The use of technology to protect workers immediately and capture valuable data to improve risk management planning for the future is critical for any organization to elevate its safety plan.