Integrated truck designs continue to evolve as manufacturers strive to increase operating efficiency, simplify operations and reduce downtime. Electronics continue to dominate advancements in Class 8 truck design. Controller Area Network (CAN) communications allow the components on trucks to communicate with each other over multiplexed wire harnesses. CAN technology makes it possible to optimize Class 8 trucks for specific applications, while the data shared through telematics systems makes it easier to diagnose and service the trucks. This results in greater fuel efficiency and increased productivity.

Recently, advancements in onboard electronic communications have led to development of advanced collision avoidance systems; the ability to capture harsh braking and acceleration events to help train drivers; and onboard diagnostic systems that use telematics systems to inform owners and dealers of impending problems in real time.

Many customers now realize the benefits that advanced electronic features can have on productivity and safety. “Our customers are demanding more innovative and sophisticated features which translate to more electrical componentry,” says Ashraf Makki, product marketing manager, Volvo Trucks.

CAN communications have progressed past merely connecting components on the truck chassis. CAN systems are now starting to communicate with truck bodies. Communication between the truck and body allows operating parameters to be customized for optimal performance.

“We are seeing CAN multiplexed messaging requests on a daily basis,” says John Felder, product marketing manager, Volvo Trucks.

Consider Class 8 Truck Electrical Demands

The updated electrical system on the Western Starm4700 features a third power distribution module, which provides up to 40 relays and 42 fuse positions. This update delivers an increased power capacity from 150 to 325 amps.Western Star

The updated electrical system on the Western Starm4700 features a third power distribution module, which provides up to 40 relays and 42 fuse positions. This update delivers an increased power capacity from 150 to 325 amps.Western Star

“With the increasing demand in today’s trucks, the minimum alternator size offering for Western Star is 160 amps for straight truck applications,” says Samantha Parlier, vice president, marketing and strategy, Western Star. “It can be as high as 275 amps for a highly optioned vehicle. Furthermore, all alternators are equipped with a remote sense feature, which signals the alternator to increase voltage output to compensate for voltage drop. The additional voltage forces the current into the battery faster, which results in reduced battery charge time.”

Western Star addressed these evolving demands with the recent redesign of its 4700 vocational Class 8 truck. “The updated electrical system on the 4700 features a third power distribution module, which provides up to 40 relays and 42 fuse positions,” says Parlier. “This update delivers an increased power capacity from 150 to 325 amps.”

Not all applications are going to require more power. But complex body upfits are utilizing more electronic controls that draw information from data produced by the truck chassis and are even tying in to the truck telematics systems.

“Power demands are dependent on the application,” says John Felder, product marketing manager, Volvo Trucks. “In some cases, applications require additional electrical power, while other applications require less electrical power due to the improvements of vehicle LED technology. We’ve seen an increase in data requests from body upfitters as they are seeing the value in fully understanding the functions of the truck operations.

“In terms of additional electrical power demands, additional electrical infrastructure is being offered by Volvo Trucks, and Volvo Bodybuilder Instructions (VBI) is available to provide data insights and answer any inquiries,” he adds.

Driver Safety Takes Center Stage

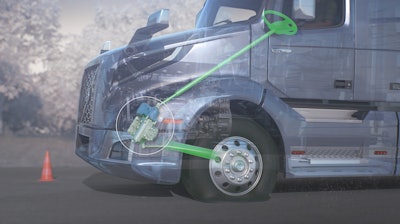

Volvo Dynamic Steering (VDS) offers a safer, more comfortable experience for drivers, improving stability when encountering corsswinds, highway crowning, soft shoulders, or emergency situations.Volvo Trucks

Volvo Dynamic Steering (VDS) offers a safer, more comfortable experience for drivers, improving stability when encountering corsswinds, highway crowning, soft shoulders, or emergency situations.Volvo Trucks

“Active safety systems have made significant leaps in functionality and features in recent years, and because of this, have gained significantly in popularity in all markets including vocational applications,” says Parlier. “Western Star started offering the Wabco OnGuard system with the introduction of our highway model, the 5700XE, in 2015. In 2019, we expanded the availability on the OnGuard system to the 4700, which is our most versatile vocational model.”

Offerings are quickly progressing beyond collision prevention and mitigation to addressing driver fatigue. “Our most recent technology announcement was Volvo Dynamic Steering (VDS), which offers a safer, more comfortable experience for drivers, improving stability when encountering crosswinds, highway crowning, soft shoulders or emergency situations,” says Makki. “Volvo Trucks recently introduced its next iteration of Volvo Active Driver Assist (VADA), a comprehensive collision mitigation system which uses radar sensors and cameras to identify and detect an object within a truck’s proximity and react accordingly.”

Cut Diagnostic Time

Electronic diagnostic software is now able to dramatically cut diagnostic time.

“Historically, vocational trucks have been full of wires and connectors, leaving the burden on the technician to sort through various connections and identify the problem,” says Mathew Long, product success, Verizon Connect. “Today’s advanced technologies are ‘repair ready,’ surfacing diagnostic information more easily and giving service managers the data to quickly troubleshoot issues and get vehicles back on the road.”

The latest advancements in telematics software simplify the data stream being produced to provide actionable data. This keeps the service from being overwhelmed by the amount of data generated by trucks in the field.

“Telematics systems help take the frustration out of endless data pools that may feel like finding a needle in a haystack,” says Long. “Rather than sifting through countless data points, telematics reporting and alerts can surface what’s important so that your team is spending time on what matters most.”

The advanced electronic systems do require additional training for service technicians. “Technicians must be certified to handle the specific software and parameter updates associated with advanced technologies such as VDS and VADA. Certification is available through Volvo Trucks Academy,” Makki notes.

Identify and Correct Unwanted Behaviors

Telematics data can provide insight into driver behavior. This allows you to coach drivers who may need additional training.

“Improved safety outcomes are at the forefront of emerging technologies entering the vocational truck market today,” says Long. “These technologies lend a hand in better understanding what a vocational truck is doing, and monitor driving behavior, which can lead to better coaching and reduced accidents. Our smart video dash cam provides AI-classified videos directly to fleet managers so they can take action on a driving event without sifting through hours of video.”

Telematics Enhance ROI

Collision prevention and mitigation technology first appeared on Class 8 over-the-road trucks. Now this technology is finding its way into the vocational truck market.Volvo Trucks

Collision prevention and mitigation technology first appeared on Class 8 over-the-road trucks. Now this technology is finding its way into the vocational truck market.Volvo Trucks

“Vehicle manufacturers have a vested interest in ensuring their customers get full value from the vehicle,” says Long. “OEMs actively make vehicle data available to third parties to help ensure vehicle owners get a holistic view of their vehicles. The best-in-class telematics solutions offer both OEM and aftermarket hardware for customers based on the needs of their business.”

There is a standard in place that defines the data available for third-party telematics suppliers. “The Association of Equipment Management Professionals (AEMP) introduced a telematics standard in 2010,” says Long. “The standard has evolved over time and AEMP 2.0 (also known as ISO 15143-3) is the most recent version. Parameters of the standard include location, asset identification, operating hours or miles, fuel burn, engine temperatures, fuel level, idle time and average power percentage.”

Manufacturers still have access to data that may not be available to third-party vendors. “Volvo Trucks’ in-house telematics services have a much larger threshold of information that can be shared, like data from remote programming and remote diagnostics, compared to third-party telematics solutions with which we share limited information,” says Makki. “In terms of open architecture, third-party telematics capture only the needed data.” ET