The city block called Marshall Field’s State Street was at one time made up of several smaller clusters of buildings bordering State, Washington, Wabash and Randolph streets. These were designed and built between

The space provided many other services other than the retail space, such as kitchens that produced the famous Frango mints candy, fur coat storage vaults that were two stories high, large water storage tanks for fire suppression, a walk-in bank vault, carpentry shop, and a garment pressing and alterations shop, all of which were removed

Environmental concerns included asbestos-containing items, lead-based paint, silica, mercury switches, PCBs and heavy metals. The process was overseen by the Kinsale Contracting Group team and Midwest Environmental Consulting Services Inc. to ensure the safety of all employees and the public. Air monitoring was a constant part of this process.

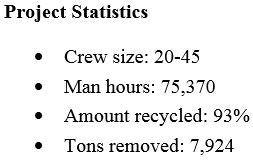

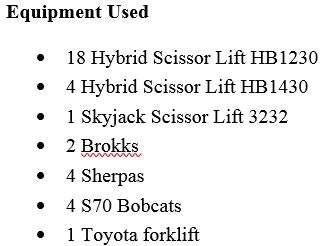

Safety was critical in the performance of the project. Crews worked day and night shifts to accommodate the retail space and public. A daunting task was moving the large amount of demolition debris throughout the building and off the loading dock. Scaffolding and catch deck/nets were installed to separate the upper floors from the lower floors within the skylight atrium. Scaffolding was erected in the main atrium of escalators and stairs that served the retail space in an open 200 foot high grand entryway. A total of 29 escalators were removed from the project. Prior to each day’s tasks, PTSAs were developed and reviewed by the entire team that were performing the work. Special consideration was taken as the building remained occupied for the duration of the work. The public continued to shop and dine throughout the remaining seven floors and lower level of the building.

The project will allow for office space, fitness club and a rooftop amenities space. This will facilitate a unique atmosphere for employees to work, shop, dine and entertain within a space that was previously underutilized.

“We attribute the success of the project to the team mentality from the general contractor down to all the trades involved working together and pre planning for the following trades task,” says Robert Duermit, Kinsale’s president. “Always keeping in mind who was working in the space and who was scheduled to work in the space next.”