One of the more common issues that can create problems with modern engine aftertreatment systems are air leaks in the intake and aftertreatment plumbing. “Air leaks typically impact the engine and aftertreatment system by affecting engine combustion, and changing characteristics of the exhaust,” says Jeff Granger, director of technical services North America for quality and satisfaction, Volvo Group Truck Technology. “Typically boost air leaks, or improperly serviced air intake systems, result in excessive engine-out soot for the DOC and DPF to manage.” An audible noise change from the engine can be one clue that indicates a possible air leak. “Perform troubleshooting on the air leak causes. Also, MIL faults can indicate when the system is not performing as designed. Troubleshooting of those faults could indicate air leaks as a cause.”

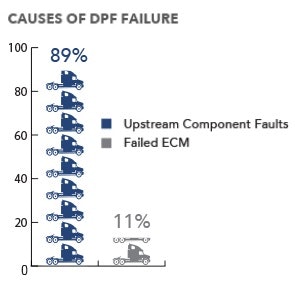

The engine’s sensors and OBD monitor air flow through the engine and can detect air leaks. “If an air leak is detected, it should be addressed. Items such as CAC hoses should be inspected for cracks or abrasion and addressed proactively,” says Jim Nachtman, Navistar's director of product marketing, heavy duty. There are only two causes of costly DPF failure, a failed ECM which is extremely rare or upstream component faults such as air leaks.Redline Detection

There are only two causes of costly DPF failure, a failed ECM which is extremely rare or upstream component faults such as air leaks.Redline Detection

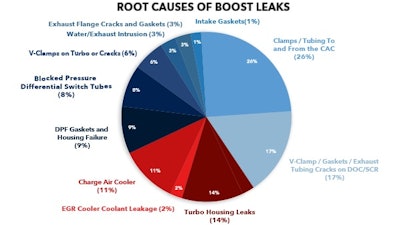

Excessive soot creation is a leading cause of downtime. “The most common cause of aftertreatment-related downtime is over-clogging of the DPF and associated too-frequent maintenance and cleaning,” says Alex Parker, Executive Vice President, Redline Detection. “The root cause of this over-clogging is unmetered air leaks that cause the vehicle to throw on more fuel, costing fuel economy and making a richer mix that quickly clogs up DPF filters, increasing costs of DPF maintenance and cutting into uptime. Finding and fixing unmetered air leaks is essential to solving aftertreatment problems.”

Identify Leaks

Leak testing should become part of your regular routine. “The best practice being used by large fleets is to perform a ten-minute leak test as part of routine maintenance,” says Parker. “For trucks in severe service conditions, leak detection as part of regular scheduled maintenance for intake and exhaust systems is absolutely essential, just like changing the oil. Because air leaks in the intake and exhaust system are the most common cause of aftertreatment failure and excessive maintenance, maintaining the seal and integrity of your intake and exhaust systems will give you the biggest payoff. The ROI is clear: Adding a high-pressure leak test into routine maintenance will give you substantial savings of time and cost in the diagnosis and repair of problem vehicles and increase your uptime.”

Air leaks will occur over time. “As vocational vehicles cover millions of miles, often in grueling conditions and inclement weather, the best-made vehicles, tight when they rolled off the assembly line, rumble loose,” notes Parker. “Those jarred, cracked and worn components are often the root cause of hard-to-diagnose aftertreatment problems.”

Any time an aftertreatment system has been serviced, check for leaks. “It’s essential to leak test a vocational vehicle after routine DPF cleaning to ensure that a leak has not been unintentionally created during the reinstall of the filter,” says Parker. “An efficiently functioning intake and exhaust needs to be completely sealed to run at peak efficiency. Air leaks are often overlooked, causing sensors to communicate bad data, then sensors are unnecessarily replaced as bad. Fleet operators can cut parts and labor costs, avoiding ‘parts darts’ replacement of expensive components by leak testing to pinpoint the problem. Faulty components creating air leaks are most frequently inexpensive gaskets, valves and clamps.”

It is easy for the technician to inadvertently introduce air leaks into the system. “In the event of any engine repair, it’s essential to ensure that the intake and exhaust are completely sealed for efficient operation of the aftertreatment system,” says Parker. “A ten-minute leak test will confirm the system’s integrity with 100 percent certainty.”

“Even small air leaks can cause early plugging of the DPF, increasing maintenance costs, hurting MPG and cutting into uptime,” says Parker. “Ultimately, a simple air leak can cause a lean condition that will cause an excess of temperature in the exhaust system, which can cause a thermal event, rendering the DPF inoperable and triggering a costly replacement. This thermal event can cause an excessive NOx condition, causing the engine to burn through DEF fluid fast.”

Tool Saves Repair Time

The results of successful leak detection and repair have been impressive. Technicians have reported that 96 percent of excessive forced regens are being eliminated. Fleets are also reporting an increase in fuel mileage by eliminating performance-killing upstream air leaks. By ending unresolved upstream faults and the associated aftertreatment issues, the technology is dramatically cutting warranty costs and comebacks.

More Resources

Tier 4 Makes Construction Equipment Repairs a Tough Nut to Crack

Construction Trucks: Don't Let Reliability Go Out the Pipe