By Gregg Wartgow, Contributing Editor

There is no disputing the benefits telematics can have for a construction company. There is also no disputing the fact that telematics requires a serious commitment.

“Telematics is a significant financial investment with a recurring cost,” says Mark Monroe, associate director of operational improvement for Summit Materials. “Leadership wants to know that telematics will be a good use of capital. They want to know how the technology will be implemented to help ensure the return on investment is aligned with company goals.”

When asking company leadership to invest in telematics, equipment managers should make a compelling presentation based on data, while also sparking some excitement around the cultural transformation telematics can help bring about.

Show the payback

When first pitching the need for telematics, equipment managers can have a hard time because no historical data is available. Monroe asked potential telematics suppliers for case study data so he could begin building a case of his own.

“We learned that many of their ROI models were a little ambitious,” Monroe says. “We looked at our fleet and made some more conservative estimates, often half of what the suppliers suggested.” Those conservative estimates put Monroe’s team in a better position to achieve its goals, while still allowing for a speedy ROI.

3 Tips to Get Quick Telematics ROI

Kevin Schlangen, CEM, is fleet manager for Dakota County Fleet Management in Minnesota. He also had to rely on industry data to help illustrate the opportunities telematics could afford. “When we started with telematics in 2005, there wasn’t much industry data available,” Schlangen relates. “By 2011 there was a lot of it. Now there is even more.”

Data or no data, Schlangen says he was still met with some initial resistance. “The biggest thing we heard was that big brother would be watching everybody,” Schlangen says. “That required a lot of discussion on what our intent was with telematics and what we wanted to get out of it.”

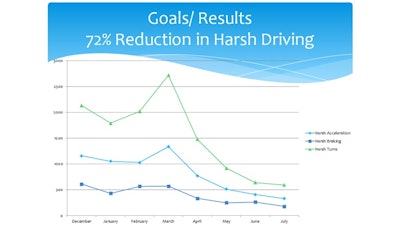

Schlangen came forward with “employee safety” as a primary goal. He explained how the monitoring of vehicles and driver behavior would help reduce accidents and injuries. He also tied that to a cost component.

“There is always a big difference in maintenance and repair costs when comparing a vehicle that is well taken care of and one that isn’t,” Schlangen points out. “If telematics could help us curtail the more aggressive driving behaviors employees sometimes exhibit, that would not only help improve safety, but also reduce costs.”

Bringing Drivers under Control with Telematics

A huge cost focus for Schlangen was fuel. He determined that if a vehicle’s fuel usage could be reduced by roughly 6%, the cost of the telematics device would be offset. “From everything I had heard about telematics, I actually thought we could reduce our fuel usage by 10%, so 6% was a safe estimate,” Schlangen says.

For Jeff Bremer, CEM, it was also important to establish an expectation that captured leadership’s attention – without setting himself up for failure.

“The biggest challenge with any technology is that it’s hard to quantify the benefits because you haven’t had any experience yet,” says Bremer, equipment director for Summit Materials’ Kansas Companies. “We decided to base our entire telematics effort on fuel savings alone. We knew telematics would help us accurately monitor idle time. Then we could work with operations to reduce it. We decided to focus on machines that were idling in excess of 20%.” Bremer then determined that a modest 3% fuel savings would pay the monthly service fee for a telematics device.

Telematics Cut Contractor's Fuel Costs $54,000 per Year

Randy Bosman, CEM, is equipment manager of the Washington state region for Granite Construction. He says the company has always seen the value of telematics. For him, it helped to stick to the basics at first, keeping things simple and measurable. He focused on basic asset location and utilization. From there he started leveraging telematics to gather meter data, as well as manage idle time, driver/operator behavior, and equipment alerts/malfunctions.

“There is a considerable savings from not having to go out and manually collect meter readings,” Bosman says. “Figure out how much money can be saved if it takes an employee 15 minutes per asset on a monthly basis. There is also a safety aspect to this since employees don’t have to be climbing on and off equipment.”

Tax reporting is another area where telematics can have a tangible payback. “When vehicles cross state lines, telematics can significantly simplify IFTA (International Fuel Tax Agreement) reporting preparation,” Monroe says. “Also, if retail fuel is purchased and used for off-highway activities such as paving and construction projects, telematics data can be leveraged to get credits back for taxes paid.”

Construction Telematics Improves Site Efficiency, Simplifies Tax Rebates

With the right telematics solution, inspecting vehicles is another area where tangible payback can be achieved. Similar to manual meter readings, the human time spent conducting vehicle inspections is significant. Telematics-based inspections help save time and streamline processes.

Spelling out the benefits and opportunities

Telematics can help a company save money in many ways. Some aren’t as easy to articulate as reduced fuel use and labor time. Nonetheless, company leadership should be made aware of the opportunities.

An example is the improved preventive maintenance scheduling telematics helps achieve. Telematics provides real-time machine performance data and diagnostic alerts. “Avoiding a major breakdown and repair bill is another one that is hard to prove, though,” Monroe points out. That’s because it is an avoided cost, not necessarily a saved cost. “It’s easier to get this benefit across to leadership if you’ve had a major breakdown in the past that cost the company a lot of money,” Monroe adds.

Telematics Help Turtle Construction Run Milling Machines with 1% Downtime

Reduced liability exposure has been a benefit Schlangen likes to call attention to. Telematics helps track where a given vehicle is at all times, along with what it is doing.

“If there ever is an accident, an insurance company will typically say you’re at least partially at fault,” Schlangen says. “When telematics is installed on your vehicle, you have insights into the accident. Maybe somebody ran a stop sign and pulled out in front of your driver. Your driver took evasive action but couldn’t avoid a collision. That actually happened to us once, and it’s the only time I can remember where the other driver’s insurance company paid 100% of the claim. Leadership will appreciate that.”

How to Make Telematics a Tool for Managing Machine Life and Projects

The location tracking telematics provides is another benefit both public and private sector leadership can appreciate. Private companies can better establish employee accountability because you can track where vehicles are at all times. Public entities will appreciate that too, along with an additional side benefit.

“We had a curious taxpayer give us a call once,” Schlangen relates. “He wondered why we were paying an employee to hang out at a convenience store. I pulled the telematics report and got my facts straight before responding. I was able to see that this employee had spent all day at a nearby jobsite. I shared that with the caller, adding that it only seemed reasonable that the employee would stop for a bottle of water before driving back to the shop. The taxpayer was somewhat stunned that we could track that sort of thing. The taxpayer was also really appreciative. The county officials were too, because that is the kind of accountability and transparency they are looking for.”

Another benefit of telematics-based location tracking is asset utilization. Telematics data tells you how often vehicles and equipment are really being used.

Immediate Drop in Machine Costs Spurs Herzog Contracting to Greater Telematics Use

“We pitched the idea of actually being able to reduce the size of our fleet,” Schlangen says. “Manually collecting meter data won’t help you do that. First of all, it can be inaccurate. Secondly, meter data doesn’t differentiate between operating time and idling time. Telematics does. Over the course of a few years, we were able to reduce the size of our fleet by understanding which vehicles were actually needed.”

3 Ways Telematics Increase Construction Equipment Security

Bremer says theft prevention can be another big selling point with company leadership. But again, “You don’t know what you don’t know,” Bremer points out, referring to the fact that it’s hard to put a value on the benefits of a system unless you have experienced or been introduced to them. This is why he decided to base his ROI discussion solely on idle time reduction. Theft prevention is just one of the many side benefits company leadership might like to hear about.

Implementation and goal achievement

Leadership also wants to know how goals are going to be met. For Schlangen, that required employee education and supervisor empowerment.

“Once telematics was put in place, I needed to make it clear to leadership that reporting would also be in place,” Schlangen says. “We set it up so that every month we could send reports to key people in different county departments. A report showed things like idle time and speeding—things that contributed to excess fuel consumption. All of this data was on a single piece of paper so it was easy to read.”

Schlangen has also found that starting slowly can help build a stronger case for telematics. He has gone the route of pilot projects, which allows management to see if real life data is in alignment with expectations. When the data is in alignment, it becomes easier to make the argument that telematics should be expanded further.

“When we started with telematics in 2005, we only had it on our snowplow trucks,” Schlangen says. “That went very well. In 2011 we expanded into other on-road vehicles. That also went well. After a year or so, everyone was convinced that telematics was a great investment and we rolled it out to our entire 300-plus vehicle fleet.”

Keys to making a compelling presentation

Data is going to be a big part of any telematics-themed presentation. Easy-to-understand charts and graphs are essential. Schlangen showed simple line graphs that forecasted month-to-month progress over the course of a year. Schlangen is also a big believer in photos—photos of equipment and vehicles in their actual working environments.

“As an equipment manager, you need to use every tool available,” Schlangen says. “I do everything in PowerPoint. It’s not always fun to stand up in front of a crowd and speak. I love my job, though, and it’s important to get that across through the passion you display when presenting.”

Bremer also likes putting slideshow presentations together. His advice is to be straightforward and succinct. Have your data in place and provide some examples and likely scenarios. “We said we expected to reduce idle time by 10%, and that would result in X fewer gallons of fuel that would result in X fewer dollars spent per month. That’s the type of thing leadership is looking for,” Bremer says.

Bosman says it’s important to talk about the telematics partner you’re leaning toward. Doing so helps instill confidence in leadership that you’ve done your homework and are thinking ahead to the implementation phase.

“It was important for us that the telematics provider recognized the AEMP data standard,” Bosman says. “We also wanted to know about data storage, how long data would be available, and privacy issues.”

“The most beneficial thing you can do when evaluating suppliers is to establish must-haves and nice-to-haves during the comparison,” Bremer adds. “This will assist in getting the expected outcome after the implementation.”

Monroe’s biggest piece of advice is to prepare carefully, but don’t overwhelm the audience. “Two or three slides with basic information based on data and potential benefits is enough,” Monroe says. “Keep it simple. If there is interest, then you can start to dig deeper.”

Equipment managers also need to be patient. “You might have to present your idea four or five times. Leadership has a lot of other things it is thinking about,” Bremer says.

By having your data-supported pitch in place, you’ll be prepared to sell the telematics sizzle at the most opportune time. “It’s never about throwing telematics in their face,” Bremer adds. “It’s about making leadership aware of the opportunities a telematics solution can provide.”

More Resources

How Kokosing Uses Telematics to Improve Operator Skill and Safety